Using Aroma Oils

Solder Fittings

When using solder fittings use only tin base solder with a melting point below 315

ºC

.

Do not overheat. Ends of water supply tubing must be thoroughly cleansed for a minimum

distance of 25mm from ends. Do not remove valve cover.

To Check Operation

1. Turn on SAWO and allow tank to fill with water.

2. Turn off SAWO control. Water should stay in tank.

3. Turn off power at the panel box. Water should discharge from tank.

4. Turn on power at panel box.

5. Repeat.

PROVIDE DRAIN PLUMBING ACCORDING TO LOCAL REQUIREMENTS.

PLUMB AS REQUIRED FOR GRAVITY DRAIN SYSTEM.

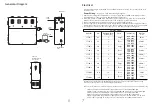

Aroma oil

10ml bottle with

integrated

dropper

Recess for

essential oil

Steam head

(install per instructions

on page 5)

Steam emission slot

Optional Automatic Drain System

12

!

CAUTION

!

CAUTION

!

CAUTION

Enjoy aroma oils by placing a drop or

two into your steamhead as shown in

the attached illutration. Only use SAWO

aroma oils in a SAWO steamhead, or any

other equivalent oil deemed suitable for

use in the SAWO steamhead.

Use aroma oils with caution.

aroma oils are for external use only. Keep

out of reach of children. aroma oils are highly

concentrated and are potent substances and

should not be applied directly to the skin as they

can be irritants. Use aroma oils with caution.

Place the drops into the SAWO steamhead recess prior to turning on the

steambath. Do not place drops in a hot steamhead as SERIOUS INJURY CAN RESULT IF YOU

DO NOT FOLLOW THIS WARNING.

Start with one drop to gauge strength and suitability. Limit to a maximum of a few

drops during a steambathing session. Some people may find that the aroma makes dizzy and

the user should exit the steam bath IMMEDIATELY. If skin irritation occurs stop using the oils

immediately. Remove any excess oil by washing in mild soap and water. If ingested, rinse

mouth with water. Administer water or milk to dilute. contact a physician immediately.

13

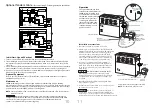

Model No

.

kW

St

eam Room

V

olume (m³)

Light walls

(t

emper

ed glass

,

acr

ylic

, et

c.

)

Hea

vy walls

(tiles

, c

oncr

et

e,

et

c.

)

V

oltage (

V

)

W

ir

e Siz

e

mm²

Length

Width

Height

Siz

e

of St

eam G

ener

at

or (mm)

cbm

wt.

kg

C

ar

ton Bo

x

Phase

C

u

rr

ent (A)

STR45-1

4.5

6.0mm²

1

4mm²

3

4mm²

3

2.5mm²

3

8.0mm²

1

2.5mm²

3

6.0mm²

1

2.5mm²

3

2.5mm²

3

4mm²

368

502

502

368

368

368

368

368

368

368

171

200

200

171

171

171

171

171

171

171

375

466

466

375

375

375

375

375

375

375

0.07

0.12

0.12

0.07

0.07

0.07

0.07

0.07

0.07

0.07

14

21

21

14

14

14

14

14

14

14

1

20A @ 380V 21A @ 415V

16A @ 380V 17A @ 415V

12A @ 380V 13A @ 415V

10A @ 380V 11A @ 415V

8A @ 380V 9A @ 415V

35A @ 220V 38A @ 240V

29A @ 220V 32A @ 240V

23A @ 220V 25A @ 240V

6A @ 380V 7A @ 415V

18A @ 220V 19A @ 240V

380 - 415

380 - 415

380 - 415

380 - 415

220 - 240

380 - 415

220 - 240

380 - 415

220 - 240

220 - 240

STR45-3

4.5

STR60-1

6.0

STR60-3

6.0

STR75-1

7.5

STR75-3

7.5

STR90-1

9.0

STR90-3

9.0

STR120-3

12.0

STR150-3

15.0

2 - 6

2 - 6

4 -13

4 - 13

5 -18

5 - 18

12 - 24

12 - 24

20 - 30

23 - 35

2 - 4

2 - 4

3 - 8

3 - 8

4 - 12

4 - 12

6 - 16

6 - 16

12 - 20

14 - 25

TECHNICAL DA

T

A

*F

or steam rooms with v

entilation,

please use higher k

ilo

w

att steam gener

ators

.

*F

or steam rooms with v

entilation,

please use higher k

ilo

w

att steam gener

ators

.

Subjec

t to change without prior notic

e.

16A @ 380V 17A @ 415V