17

English

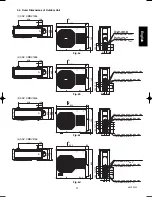

(4) With the “Lo” knob of the manifold valve open and

high-pressure valve (“Hi”) closed completely, run

the vacuum pump. Run the pump until the pres-

sure is –101 kPa (–76 cmHg). The operation time

for the vacuum pump varies with tubing length and

the capacity of the pump. The following table

shows the amount of time required for evacuation:

Table 5

The required time in the above table is calculated

based on the assumption that the ideal (or target) vac-

uum condition is around 10 mmHg abs.

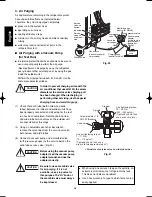

(5) With the vacuum pump still running, close the “Lo”

knob of the manifold valve. Then stop the vacuum

pump. Fully close the low-pressure valve and stop

the vacuum pump. (Wait 1 – 2 minutes and check

that the manifold gauge pointer does not return. If

it does return, find and repair the leak, then apply

the vacuum again.)

(6) With a hex wrench, turn the valve stem on the nar-

row tube service valve counter-clockwise by 90

degrees (1/4 turn) for 10 seconds, and then turn

the stem clockwise to close it again.

(7) With a standard screwdriver, turn the wide tube

service valve stem counterclockwise to fully open

the valve.

(8) Turn the narrow tube service valve stem counter-

clockwise to fully open the valve.

(9) Loosen the vacuum hose connected to the wide

tube service port slightly to release the pressure.

Then, remove the hose.

(10) Leak test all joints at the tubing (both indoor and

outdoors) with liquid soap. Bubbles indicate a leak.

Be sure to wipe off the soap with a clean cloth.

NOTE

CAUTION

Be sure to completely insert

the hex wrench before

attempting to turn the valve.

Required time for evacuation when capacity

of 100 liter/h vacuum pump is used

20 min. or more

CAUTION

If a CFC gas detector is used,

use a special detector for HFC

refrigerant (such as R410A and

R134a).

08-253 CMRV3146EH_OU EN 10/14/08 2:39 PM Page 17