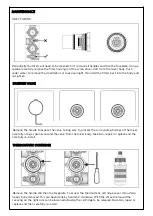

Remove the handle and first make sure the calibration ring is in the correct 12 o'clock position. if

not, place the calibration ring in the 12 o'clock position and re-test. If the calibration ring is in the 12

o'clock position carefully remove.

Open an outlet place a thermometer under the flowing water and adjust the spindle on the

cartridge, right for colder, left for hotter until 38°C is achieved. Place the calibration ring back in

the 12 o’clock position and re-install the hand ie. Re-test to ensure the valve is working correctly.

COMMISSIONING

To Commission a thermostatic mixer firstly check the following: (requirements on page 2)

1.

The supply water temperatures are within the valves operating range.

2.

The supply working pressures are within the valves operating range.

3.

The supply working pressures are balanced

4.

Isolating valves (and strainers preferred are provided.

With the temperature control handle in the 12 o’clock position open a water outlet.

Using a thermometer, measure the mixed water temperature at the outlet. If 38°C is achieved the

temperature valve is working correctly. If the temperature is above 38°C re-calibration may be

required. (Please see CALIBRATION)

Carry out the cold-water supply isolation test by isolating the cold water supply to the valve, wait for

five seconds the valve may stop flowing or if water is still flowing check that the temperature is below

46°C.

CALIBRATION

If the mixed water temperature is above or below 38°C you may need to re-calibrate the cartridge.

Summary of Contents for KOY

Page 1: ...KOY ZEPHYR THERMOSTATIC SHOWER MIXER www sanipexgroup com ...

Page 2: ......

Page 4: ... ...

Page 14: ...Note ...

Page 15: ...Note ...

Page 16: ...INM KOY ZEP THERMO_MIXER 08 21 www sanipexgroup com ...