Summary of Contents for VP-D371

Page 12: ...Product Specification 2 4 Samsung Electronics MEMO ...

Page 46: ...4 18 Disassembly and Reassembly Samsung Electronics MEMO ...

Page 66: ...Exploded View and Parts List 5 20 Samsung Electronics MEMO ...

Page 83: ...Samsung Electronics 8 1 8 Wiring Diagram ...

Page 84: ...Wiring Diagram 8 2 Samsung Electronics MEMO ...

Page 93: ...PCB Diagrams Samsung Electronics 9 9 9 10 CVF PCB COMPONENT SIDE CONDUCTOR SIDE ...

Page 94: ...PCB Diagrams 9 10 Samsung Electronics MEMO ...

Page 118: ...Schematic Diagrams 10 24 Samsung Electronics MEMO ...

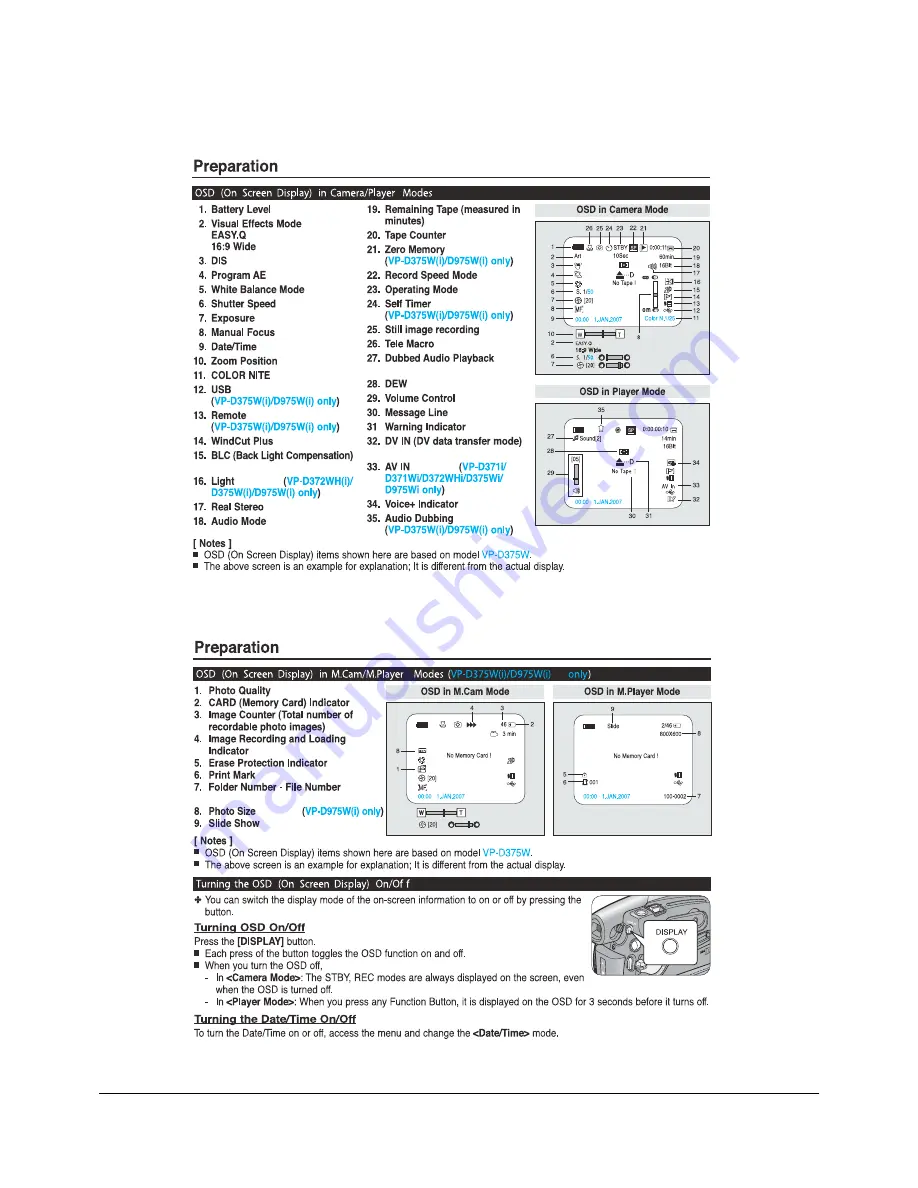

Page 119: ...Samsung Electronics 11 1 11 Operating Instructions ...

Page 120: ...Operating Instructions 11 2 Samsung Electronics ...

Page 121: ...Operating Instructions 11 3 Samsung Electronics ...

Page 122: ...Operating Instructions 11 4 Samsung Electronics ...

Page 123: ...Operating Instructions 11 5 Samsung Electronics ...

Page 124: ...Operating Instructions 11 6 Samsung Electronics ...

Page 125: ...Operating Instructions 11 7 Samsung Electronics ...

Page 126: ...Operating Instructions 11 8 Samsung Electronics ...

Page 127: ...Operating Instructions 11 9 Samsung Electronics ...

Page 128: ...Operating Instructions 11 10 Samsung Electronics ...

Page 129: ...Operating Instructions 11 11 Samsung Electronics ...

Page 130: ...Operating Instructions 11 12 Samsung Electronics ...

Page 131: ...Operating Instructions 11 13 Samsung Electronics ...

Page 132: ...Operating Instructions 11 14 Samsung Electronics ...

Page 133: ...Operating Instructions 11 15 Samsung Electronics ...

Page 134: ...Operating Instructions 11 16 Samsung Electronics ...

Page 135: ...Operating Instructions 11 17 Samsung Electronics ...

Page 136: ...Operating Instructions 11 18 Samsung Electronics MEMO ...

Page 148: ...Troubleshooting 12 12 Samsung Electronics MEMO ...

Page 168: ...Circuit Operating Description 13 20 Samsung Electronics MEMO ...

Page 183: ...Reference Information Samsung Electronics 14 15 Fig 14 14 ...

Page 212: ...Reference Information 14 44 Samsung Electronics 14 5 Abbreviated word ...