Samsung Electronics

7-5

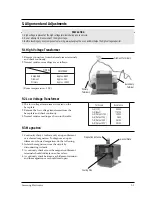

Troubleshooting

7-3 Problem Analysis

7-3-1 When inserting the power plug (function selection, door on/off)

7-3-2 When operating

Problem

location

Cause

Measures

No alphivumeric

a. Fuse (250V, 10A)

Open bad contacts

Exchange

display

b. Magnetron and case,

Exchange

temperature switch

c. Power plug and socket

Bad contacts

Exchange,repair

d. 1st and 2nd of LVT

Cut-off

Exchange

e. Connector of PCB board

Bad insertion

Repair

f. Highlight indication plate

Poor

Exchange

g. Circuit within the PCB board

Board DC fect on

PC Board exchange

Fuse is damaged a. Power transformer

Short circuit

Exchange

(short circuit)

b. Safety switch

Fusion and poor

Exchange

c. Monitor switch (short switch)

Poor operation

Latch adjustment

d. HVC

Short circuit

Exchange

e. Latch operation

Poor operation

Latch adjustment

Problem

location

Cause

Measures

Electrical

a. Grounding wire

Bad grounding

Inspection

shock

b. AC 230V power line is

Lead wire not connected

the chassis

Exposed part of the power Adjustment

line is shorting the

chassis

Lamp is not on a. Lamp and lead wire

Disconnected

Exchange/adjustment

b. Check the lamp relay

Coil disconnected

Exchange

c. Thermostat 2EA

Bad contact point

Exchange

d. LVTransformer

Is the LVT wire normal?

Exchange/adjustment

Elevation

a.Check the connections to

Poor wire connection

Adjustment

action

the elevation assembly

unsatisfactor

b. Continuity between terminals

Disconnection

Exchange/

of the elevation motor

Assembly exchange

(Measure after removing

the power leads)