3

R. 05/21 850 823

SAMOA Industrial, S.A. · Pol. Ind. Porceyo, I-14 · Camino del Fontán, 831 · 33392 - Gijón - Spain · Tel.: +34 985 381 488 · www.samoaindustrial.com

2021_05_03-13:00

EN

NOTE:

During hose installation, tighten the U-bolt just till the hose gets

slightly deformed. Do not overtighten the U-bolt, since the hose could

be damaged.

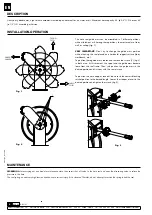

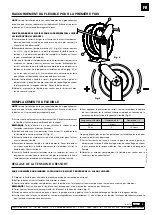

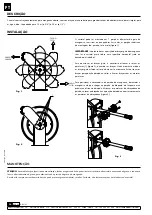

To install the hose the first time, follow the next steps:

1.

Make sure the power spring is relaxed, with no tension, in such a way that

the spool does not try to turn (the ratchet must be unlocked).

2.

Connect the new hose to the swivel (2) (fig. 4), place the U-bolt (1)

(fig. 4) in such a way that it firmly holds the hose against the spool,

and start to wind the hose into the spool turning the spool manually.

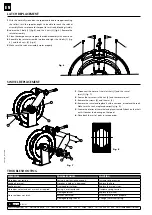

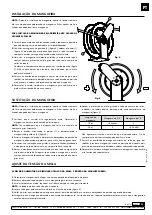

3.

Once the hose is completely wound around the spool (the power

spring still will be with no tension), apply the pre-tension to the power

spring by turning the spool the number or turns stated in the table

depending on the hose length (pag. 5), turning in positively direction

as shown in (fig. 5). Do not apply more tension than stated, as the

power spring could be damaged.

4.

Pass the hose end through the roller outlet to the desired length, lock

the spool with the ratchet in the nearest position and place the hose

stopper.

5.

Fully unwind and rewind the hose to make sure the power spring is

correctly tensioned.

HOSE INSTALLATION THE FIRST TIME

Fig. 5

Fig. 4

2

1

NOTE:

During hose installation, tighten the U-bolt just till the hose gets

slightly deformed. Do not overtighten the U-bolt, since the hose could

be damaged.

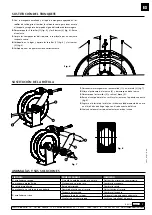

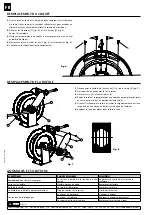

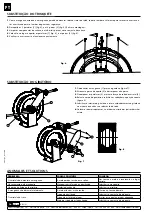

1.

Ensure the reel is firmly attached. Take the hose fully out and let the

spool blocked by the ratchet mechanism.

NOTE:

beware the spool to get loose and start turning freely.

2.

Remove the U-bolt by loosening its nuts (1) and disconnect the hose

from the swivel (2) (fig. 4).

3.

Take away the hose from the spool and remove the hose stopper in

order to use it with the new hose.

4.

Connect the new hose to the swivel. Place the U-bolt in such a way

that it firmly holds the hose against the spool, and pull the hose in

order to unlock the ratchet.

5.

Allow the hose to slowly wind into the spool and ensure to finish with

the whole hose inside the reel and the power spring with no tension

(in such a way that the spool does not try to turn).

6.

Apply the pre-tension to the power spring by turning the spool the

number of turns indicated below, depending on the power spring

version and the hose length (fig. 5):

Hose length

Hose 3/4"

Hose 1/2"

50'

+8 turns

X

65'

X

+4 turns

Do not apply more tension than stated, as the power spring could be

damaged.

7.

Pass the hose end through the roller outlet to the desired length, lock

the spool with the ratchet in the nearest position and place the hose

stopper.

8.

Fully unwind and rewind the hose to make sure the power spring is

correctly tensioned.

HOSE REPLACEMENT

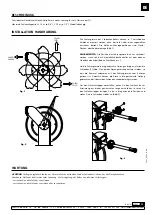

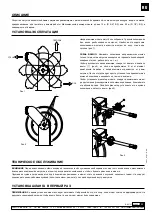

If you wish to increase or decrease the power spring tension:

1.

Pull the hose out till the first ratchet locking position.

2.

Remove the hose stopper and pull the hose out in order to unlock the

ratchet.

3.

Allow the hose to fully wind into the spool, applying some counter-

force in order to avoid the spool to turn freely.

NOTE:

beware the spool may get loose and start turning freely.

SPRING LOAD ADJUSTMENT

4.

Turn the spool to increase or decrease the power spring tension (fig. 5).

5.

Pass again the hose end through the roller outlet and place the hose

stopper in the desired position.

6.

Make sure that the hose fully winds and unwinds properly. If it does

not, repeat the previous steps until it does.