Poland, 15-161 Białystok, ul.Trawiasta 15

Established – 1984

tel. (+48) (85) 654 70 31

fax (+48) (85) 664 70 41

e-mail: [email protected]

www.samasz.pl

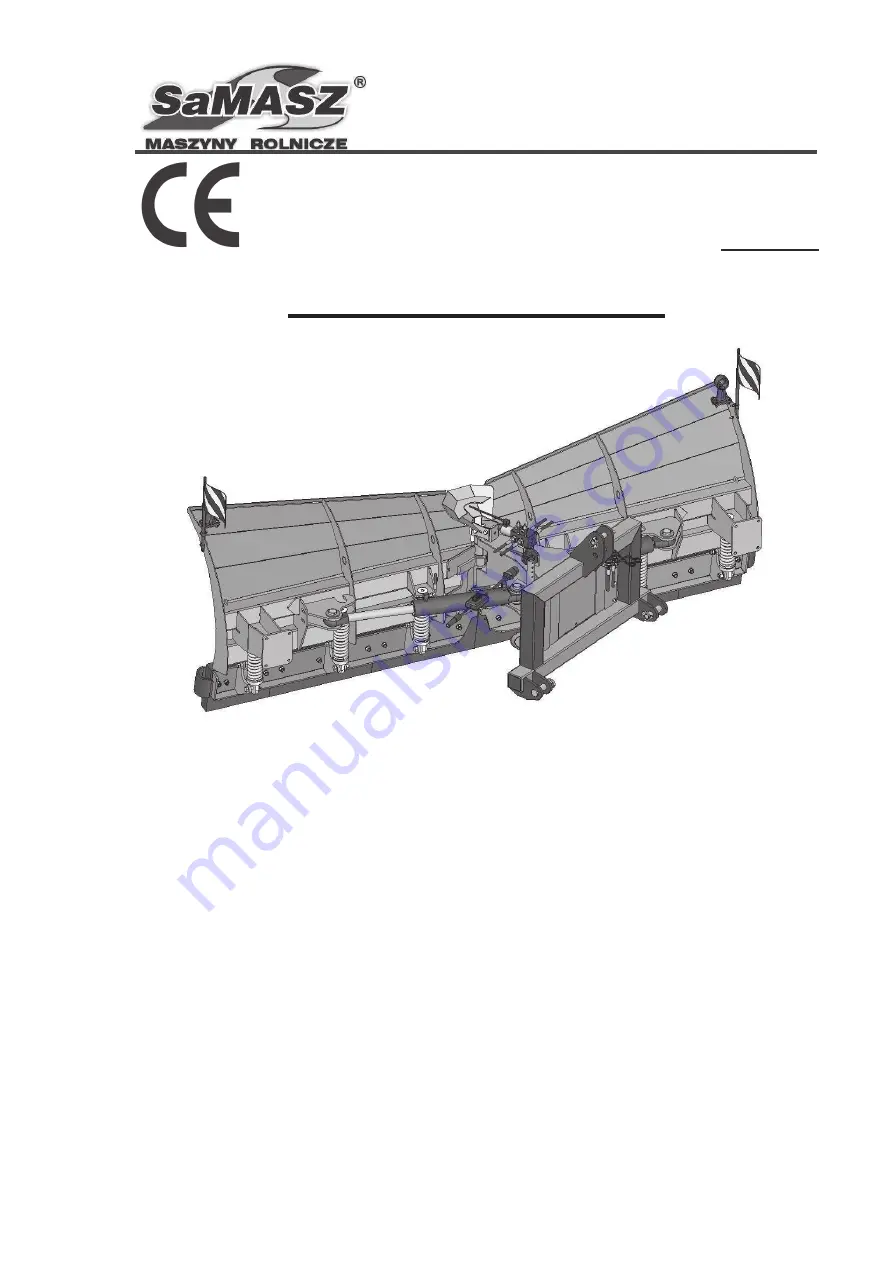

OPERATING MANUAL

MEDIUM DUTY SNOW PLOWS:

PSV 161

PSV 181

PSV 201

PSV 231

PSV 271

PSV 301

PSV 231 Up

PSV 271 Up

PSV 301 Up

PSV 231 Up (H)

PSV 271 Up (H)

PSV 301 Up (H)

The original instruction

IN202EN002

2012.10.09

VERSION 2