Operator's manual

Trailed disc mowers

KDC

- 44 -

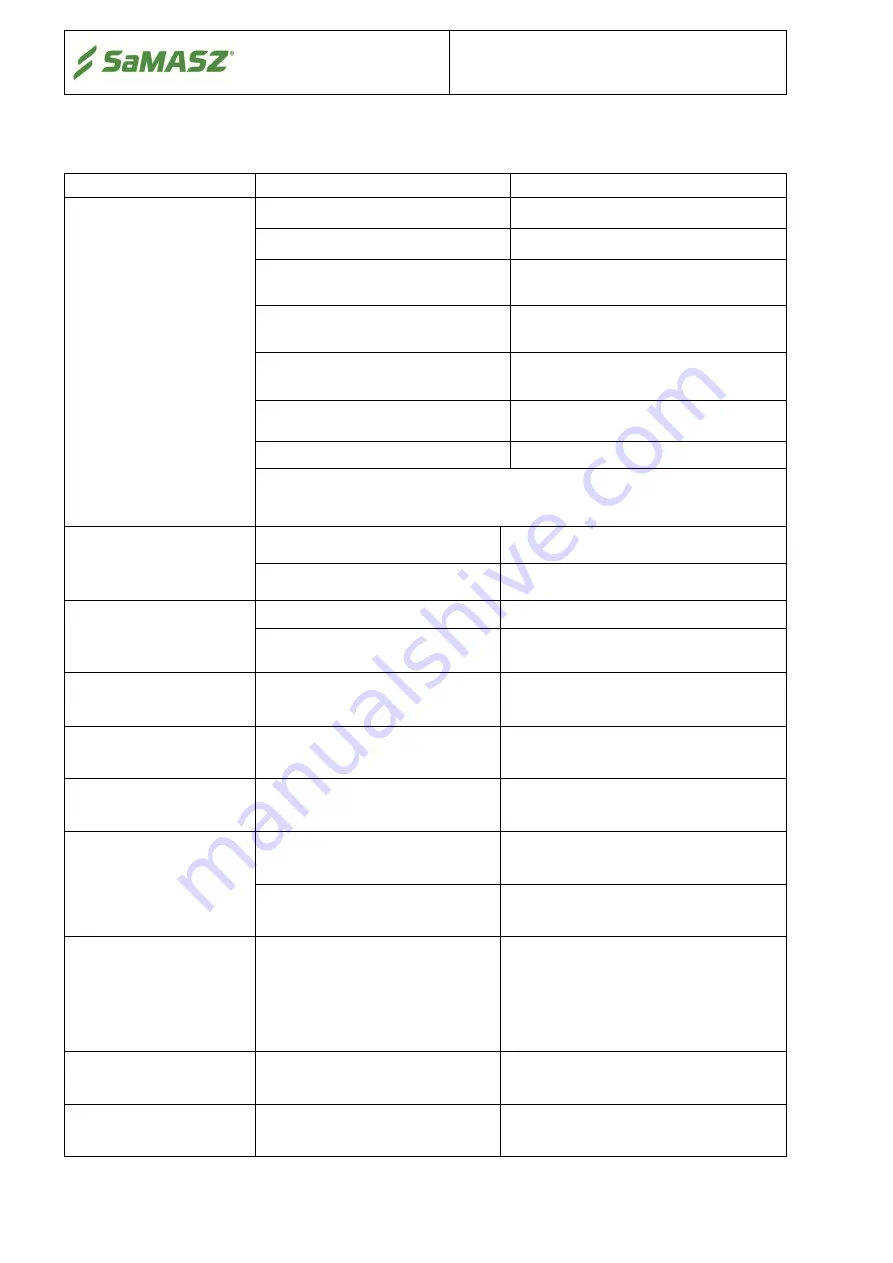

8.

DEFECTS AND THEIR REPAIR

Tab. 12.

Possible defects and their repairs

Defect type

Reason

Recommendations

Mower fails to mow or

leaves strip of uncut grass

between discs

Some of knives are missing

Mount knives

Worn knives

Replace knives with new ones

Improperly mounted knives

(left – right)

Mount knives strictly keeping

provisions found in manual

Too high tractor's engine rpm

(the most frequent mistake)

Reduce rpm

Too low operating speed

Increase driving speed above

V

≥

10 km/h

Damaged tractor's PTO shaft, drive

not transmitted

Remove defect

Laid grass

Low mowing on each occasion

It is tolerable for a mower with conditioner or rollers to mow improperly in

case of very low grass or during a rainfall

Mower is blocked

Damaged bearings in disc hub

Replace bearings

Damaged cogs in cutterbar

Examine condition of all cogs

Mower is not mowing even

though drive is transmitted

from tractor

Torn roller inside gear

Replace gear

Torn or cut down hollow on

cutterbar drive shaft

Put new hollow

Mower works excessively

loud

Too low oil level in cutterbar

Examine oil level and refill oil

Mower slows down even

though rpm value is stable

Damaged friction clutch in

cutterbar

Replace clutch

Conveyor is clogged with

grass

Too low conveyor speed

Increase – adjust so as corresponds to

grass weight

Mower is clogged with

grass – no grass guiding or

guiding is uneven

Too low mowing speed

Increase driving speed above 10 km/h or

more

Swath guides are set too narrow

Widen swath guides to the maximum

Leaking cylinder

Dirty oil in hydraulic unit of the

tractor

Replace oil in hydraulic unit of the

tractor (recommended class of

cleanliness of oil according to NAS 1638

is minimum 9-10).

Purchase repair kit of the cylinder and

replace damaged sealings

Excesive vibration during

work

Damaged PTO shaft

Check the condition of PTO shaft and if

need be replace

Oil leak in gear

Not tight assembly

Examine tightness and check oil level