Page C-1

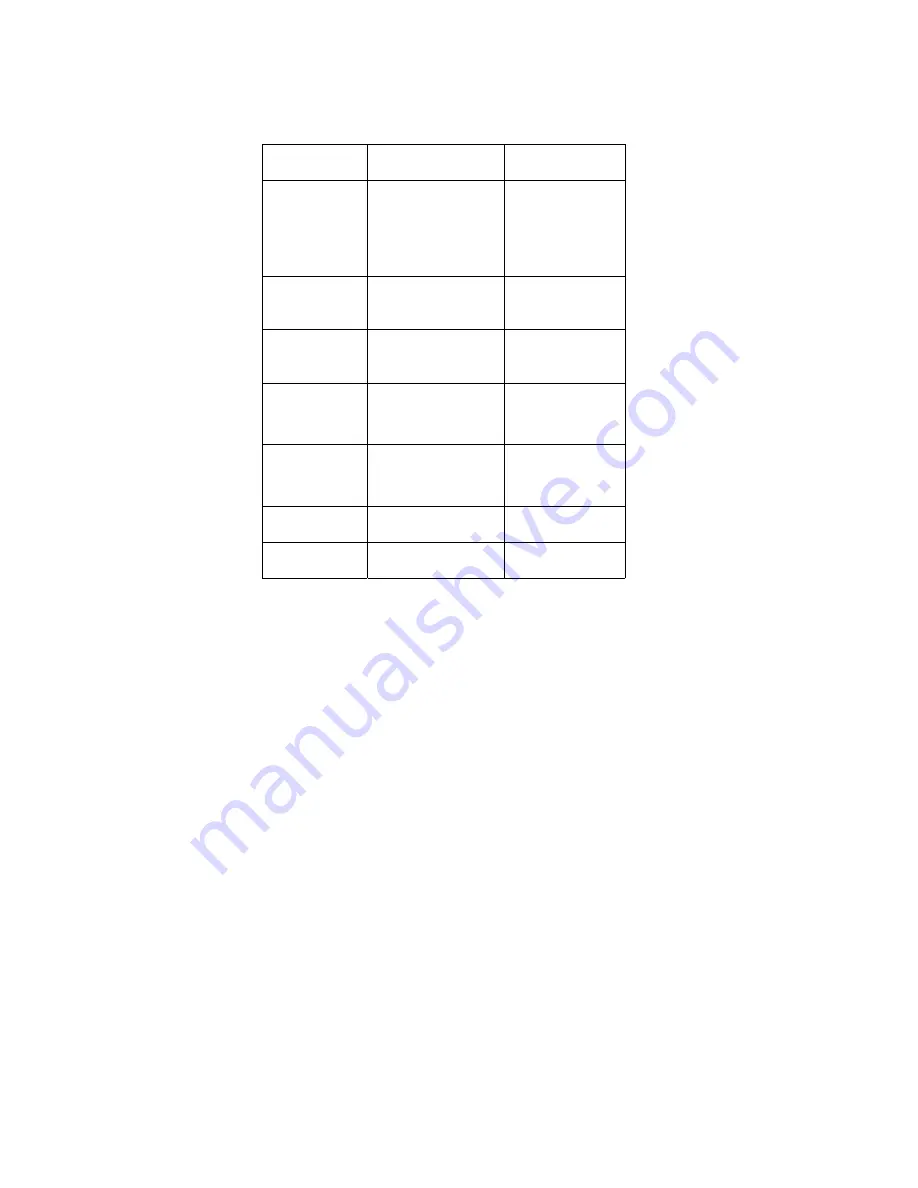

SUB-MENU

TITLE

SELECTIONS

F1

Graduations

12,000

20,000

30,000

40,000

50,000

F3

Zero Tracking

Band (SAZSM)

0d

5d

F4

Zero Reset

Range

100% (Canada

Only)

F5

Motion Band

3d

5d

10d

F6

Digital Filter

1

2

4

F12

Custom Unit

1

F13

Piece Count

1

Table 4-1: Invalid Setup Menu selections for commercial applications

4.2

SETUP MENU PROCEDURES

This section provides instructions for all of the Setup Menu procedures with the exception of the

Calibration procedures (F16 through F20) which can be found in Chapter 6.

4.2.1 CUSTOM UNIT MULTIPLIER (F11)

The custom unit multiplier is the conversion factor that you would multiply the calibration

unit by in order to obtain the custom unit of weight. For example, if your scale is

calibrated in pounds and you wish to display weight in ounces, you would enter in a

multiplier value of 16.0. The indicator automatically determines the proper display

increment for your custom unit.

1.

While in the Setup mode, scroll to "

F 11

", then scroll down once using the

ZERO

key to enter the custom unit multiplier menu.

2.

The display will momentarily show "

C U

" for the custom unit, followed by the current

value for the custom unit multiplier with the decimal point.

3.

Use the left or right directional keys (shown in Figure 4-1 below) to move the

decimal point position to the correct position. Pressing the PRINT key or the TARE

key will change the position of the decimal point.

4.

After setting the correct decimal point position, press the NET/GROSS key to save

it.

Summary of Contents for S750 Series

Page 5: ...Page C 1...