14

05/2012

English

NOTE: To close, turn the slot so that it is across the direction of flow.

7

Fit the thermal insulation shell.

CAUTION!

The plastic parts of the motor may not be heat-

insulated in order to protect the pump from overheating.

8

Connect the pipework.

CAUTION!

For the versions with stop and non-return valves, these

are already preinstalled and sealed with a tightening

torque of 15 Nm (hand-tight). Screwing with excessive tightening torque destroys

the valve screw connection and the O-ring.

When installing the valve, use a fixed spanner to prevent twisting!

5.2 Electrical connection

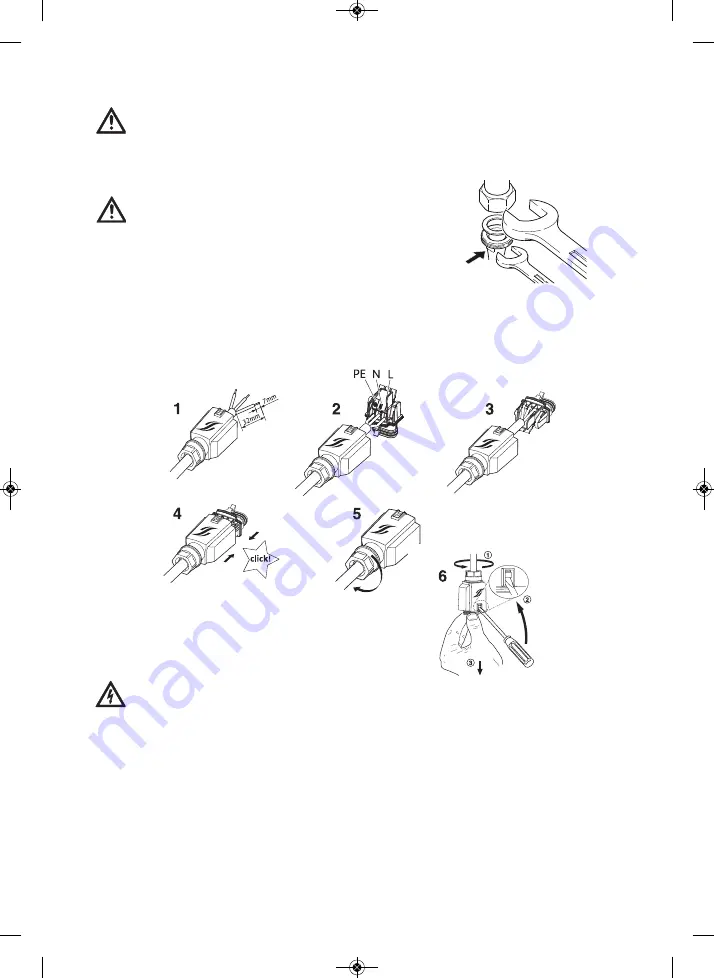

• Establish the electrical connection as follows:

• Open the Salmson-Connector as follows:

DANGER!

Only a qualified electrician is allowed to work on the electrical connection.

Before establishing the connection, make sure that the connecting cable is dead.

5.3 Filling and bleeding

• Fill the system.

• The pump rotor space bleeds automatically after a short time in operation. This

may cause noises.

If necessary, switch off and on repeatedly to accelerate the bleeding. Dry running

for short periods will not harm the pump.

NMS Zen O Home_Mise en page 1 14/09/12 08:38 Page14