56

English

Access lock

In order to lock the pump settings, it is possible

to use the « Access lock ».

To activate or deactivate it, proceed as follows:

• Put the switch 2 on ON position (Fig. 4, item S).

The <7.0.0.0> menu is called up.

• Turn the encoder to activate or deactivate the

locking. The current state of the locking is repre-

sented with the following symbols:

Lock active: Parameters are locked,

the access to menus is allowed only

on reading.

Lock inactive: Parameters can be

changed, the access to menus is allo-

wed for setting.

• Return the switch 2 on OFF position (Fig. 4, item

S). The display returns to the status page.

8.1.6 Configurations

NOTE : If the pump is delivered as separate part,

not integrated into a system we mounted, the

standard configuration mode is

« Speed control ».

« Speed control » mode (Fig. 1, 2)

Setting of the frequency by hand or external

control.

• For the starting up, we recommend to set the

motor speed at 2400 RPM.

« Constant pressure » mode (Fig. 6, 7, 8)

Regulation with a pressure sensor and setting

point (internal or external).

• The addition of a pressure sensor (with tank;

sensor kit delivered as accessories) allows a

pressure regulation of the pump (with no water

in the tank, pressurize the tank to a pressure 0.3

bar less than the pressure regulation of the

pump).

• The accuracy of the sensor shall be ≤ 1% and it is

used between 30 % and 100 % of the measuring

scale range. The tank must have a useful volume

of 8L minimum.

• For the starting up, we recommend a pressure set

value at 60% of its maximum pressure.

« P.I.D. control » mode

Regulation with a sensor (temperature, flow...) by

P.I.D.control and setting point (internal or exter-

nal).

8.2 Preliminary rinsing

The hydraulic features of every pump is tested in

factory, some water may remain in them. It is

recommended for hygien purposes, to carry out a

rinsing of the pump before any using with

potable water supply.

8.3 Filling - degassing

CAUTION!

Danger of material damage!

Never operate the pump dry, even briefly!

Pump in load (Fig. 2).

• Close the discharge valve (item 3).

• Open the venting plug (item 5), the suction valve

(item 2) and completely fill the pump.

• Close the venting plug only after water flows out

and complete aeration.

WARNING!

Danger of burn!

In hot water, a stream of water may escape from

the venting plug port.

• Take all required precautions as regards persons

and motor-converter.

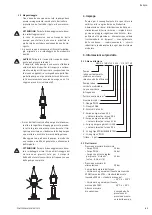

Pump in suction (Fig. 1, 5)

Two possible cases:

1st case

(Fig. 5.1)

• Close the discharge valve (Fig. 1, item 3), open

the suction valve (Fig. 1, item 2).

• Remove the venting plug (Fig. 1, item 5).

• Unscrew about 4 turns the bottom drain-priming

plug (Fig. 1, item 6) located on the pump casing.

• Put a funnel into the venting plug port and com-

pletely fill the pump and the suction pipe.

• After water flows out and total air exit, filling is

achieved.

• Screw the venting plug and the bottom drain-

priming plug back in.

2nd case

(Fig. 5.2)

• Filling can be made easier by fitting a vertical

pipe (Fig. 5, item 14) fitted with a Ø ½" stopcock

and a funnel, on the suction pipe of the pump.

NOTE: The length of the pipe must be at least 50

mm higher than the venting plug level.

• Close the discharge valve (Fig. 1, item 3), open

the suction valve (Fig. 1, item 2).

• Open the stopcock (Fig. 5, item 14) and the

venting device (Fig. 1, item 5).

• Unscrew about 4 turns the drain-priming plug

(Fig. 1, item 6).

• Completely fill the pump and the suction pipe

until water flows out of the venting plug (Fig. 1,

item 5).

• Close the stopcock (Fig. 5, item 14) (which can

be left in place), remove the pipe, close the

venting device (Fig. 1, item 5) and screw again

the drain-priming plug (Fig. 1, item 6).

CAUTION !

Risk of misuse!

Pump in load and in « Constant pressure » mode,

the detection at zero flow can not run.

• Set the non-return valve before the pressure

sensor (i.e. at pump suction if the sensor is

mounted on this one – Fig. 6).

POMPES SALMSON 06/2013

Summary of Contents for MULTI-VE Series

Page 2: ......

Page 3: ......

Page 5: ...5 11 7 6 1 13 3 2 7 100 mm Mini 200 mm Mini 100 mm Mini HA 2 BP Fig 1...

Page 6: ...8 9 12 5 11 2 3 2 7 7 4 4 6 13 10 ou or ou or 100 mm Mini HC Fig 2...

Page 8: ...Fig 4...

Page 9: ...2 14 1 Fig 5...

Page 10: ...10 17 16 ou or 15 Fig 6 10 ou or 17 15 16 Fig 7...

Page 11: ...17 16 15 Fig 8...

Page 12: ...19 18 Fig 9 Fig 10...

Page 13: ...Fig 11...