14 REVT-05ERV

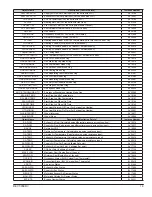

FIGURE 15 - TYPICAL CONTROLS LAYOUT

INPUT/OUTPUT

EXPANSION #1

WHEEL CONTACTOR

POWER DISCONNECT

FAC CONTROLLER

INPUT/OUTPUT

EXPANSION #2

CONTROLLER RELAYS

TRANSFORMERS

BMS CONNECTION

TERMINAL STRIP

XII - BLOWER OPERATION

A. 3 PH VOLTAGE PHASING

Three phase blower motors must be phased sequentially

to ensure correct rotation and operation. Motors are

wired in phase at the factory. Check for proper blower

wheel rotation by momentarily energizing blower demand

at the thermostat. Correct rotation is determined by

observing the wheel from the drive side and should match

the rotation decal affixed to the fan housing. If rotation is

not correct, direction can be reversed by interchanging

any two of the three field-installed leads in the base unit

control box. Make certain the connections are tight. Do

not reverse wires at blower contactor.

B. SPEED SETTING

All drives are factory set at mid-range.

1.

Determine Required RPM

- Starting with desired

supply side (outdoor air) CFM use

Chart 1

on

Page 40

to determine the internal static pressure (ISP) drop for

each option. Total these values and add the external

static pressure (ESP), then refer to

Chart 2

on

Pages

41-43

. Using this total SP (ISP + ESP) value, along

with the desired CFM, determine the RPM and BHP

required at that operating point. Adjust the blower

RPM by opening or closing the motor pulley. Loosen

the Allen screw and turn adjustable pulley clockwise

to increase RPM and counterclockwise to decrease

RPM.

Repeat this process for the return (exhaust) side to

determine the RPM and BHP requirements for that blower.

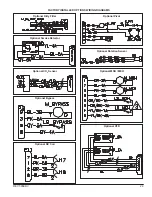

C. PULLEY ALIGNMENT

All Pulleys are laser aligned in the factory during

production, movement of the pulleys is possible however

if the set screws weren’t properly torqued down during

adjustment. Make sure blower and motor pulleys are

aligned as shown in

Figure 16

before commissioning is

complete.

D. BELT ADJUSTMENT

Maximum belt life can be obtained only if proper pulley

alignment and belt tension are maintained. Tighten new

belts after 24-48 hours of operation. This is necessary

to allow for belt stretch and for belts to seat into grooves.

1. Loosen four nuts securing blower motor to adjustable

base. To increase belt tension turn motor mount

adjustment screw counterclockwise. Turn adjustment

screw clockwise to decrease belt tension.

2. Check belt tension as follows:

a. Measure center distance (CD) between blower

and motor shafts as noted in

Figure 17

.

b. Apply force perpendicular to CD line with enough

pressure to deflect belt

1/64

inch per inch (1.5 mm

per 100 mm) of CD. Example: Deflection for a

CD of 24 inches would be

24/64

inch, or

3/8

inch.

c.

Measure belt deflection force. For a used belt,

the deflection force should be 5 lbs (35 kPa).

A new belt deflection force should be 7 lbs (48

kPa). A force below these values indicates an

under tensioned belt and a force above, an over

tensioned belt.

Summary of Contents for ENERVENT+ EVT-09 Series

Page 30: ...30 REVT 05ERV UNIT WIRING DIAGRAM ...

Page 31: ...REVT 05ERV 31 UNIT WIRING DIAGRAM CONTINUED ...

Page 47: ...REVT 05ERV 47 UNIT WIRING DIAGRAM XVIII WIRING DIAGRAMS ...

Page 48: ...48 REVT 05ERV UNIT WIRING DIAGRAM CONTINUED ...

Page 50: ...50 REVT 05ERV Optional Heat Cool Inputs Optional Pre Post Heat ...

Page 57: ...REVT 05ERV 57 DIAGRAM 15 5 1 MODULATION GAS POST HEAT DIAGRAM 14 2 STAGE GAS POST HEAT ...