17

Airflow-IQ Start-up & Commissioning Guide

Primary Probe Wiring

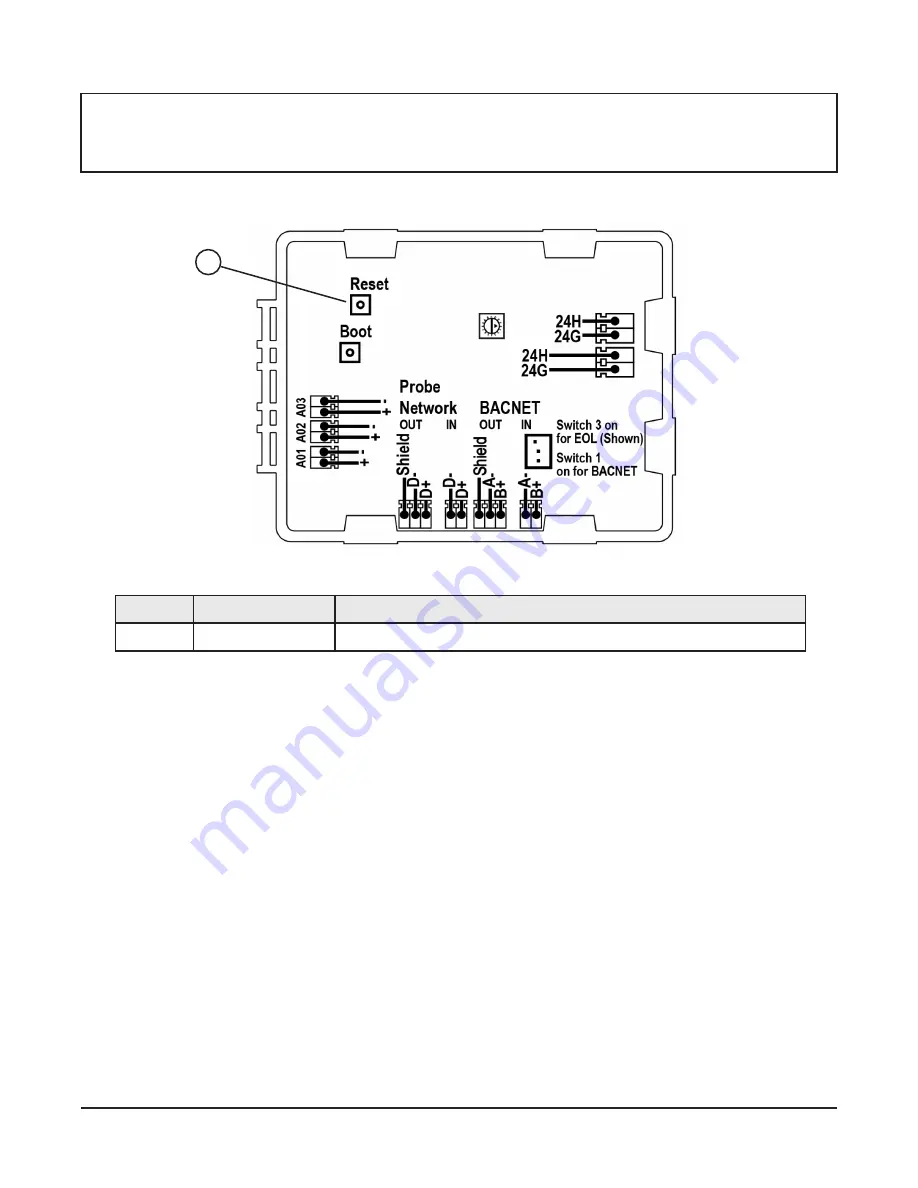

Figure 15: Primary Probe Wiring

Analog Output

1 . Carefully remove the top of the Phoenix Contact

®

screw terminal connector and insert the wires . Tighten the

terminals and reconnect them to the controller board .

2 . Connect the 4 to 20 mA analog flow output (A01: Pos and Com) and the 4 to 20 mAanalog output factory default

temperature (A02: temperature output) from the primary probe to a building automation system .

Note:

The factory default flow output is A01 . Either output A01 or A02 can be configured for temperature or flow,

or both can be configured for temperature and flow .

Probe Network

Connect the Shield, D+,and D- from the primary to the ancillary probe or remote display using the approved

communications wire . A03 is not used at this time .

Note:

The two D- and D+ connections are electrically identical .

BACnet

®

Output

1 . Carefully remove the top of the Phoenix Contact

®

screw terminal connector and insert the wires . Tighten the

terminals and reconnect them to the controller board .

2 . Connect the BACnet® output (A- and B+) from the primary probe to a BACnet network .

Note:

The two A- connections and the two B+ connections are electrically identical .

3 . Connect the shield wire from the primary probe to the Shield terminal . The shield only connects on the output end .

Note:

The Shield is connected on one end of each wire run and should never be connected on both ends of one wire .

IMPORTANT:

The primary probe provides two 4 to 20 mA signals to building automation systems . Do not apply

loop power to this probe . The system requires a two-wire power connection and separate two-wire connections

for each analog output . Analog signal outputs are isolated from power .

preliminary—this information may change

TDP05K Advanced Thermal Dispersion Probe Airflow Measuring System Installation Instructions

12

Ruskin—CONFIDENTIAL

Wiring Connections

Primary Probe Wiring

Analog Output

1. Carefully remove the top of the Phoenix Contact® screw terminal connector and insert the wires. Tighten the

terminals and reconnect them to the controller board.

2. Connect the 4 to 20 mA analog flow output (A01: Pos and Com) and the 4 to 20 mA analog output factory

default temperature (A02: temperature output) from the primary probe to a building automation system.

Note: The factory default flow output is A01. Either output A01 or A02 can be configured for temperature or flow,

or both can be configured for temperature and flow.

Probe Network

Connect the Shield, D+, and D- from the primary to the ancillary probe or remote display using the approved

communications wire.

BACnet® Output

1. Carefully remove the top of the Phoenix Contact screw terminal connector and insert the wires. Tighten the

terminals and reconnect them to the controller board.

2. Connect the BACnet® output (A- and B+) from the primary probe to a BACnet network.

IMPORTANT: Do not run the probe wiring in the same conduit as AC power wiring or with wiring used to supply

highly inductive loads, such as motors, contactors, and relays. Fluctuating, erratic, and inaccurate signal levels

are possible when AC power wiring is present in the same conduit as the signal lines. Run the wiring away from

variable frequency drives and broadcast antennas.

IMPORTANT: The primary probe provides two 4 to 20 mA signals to building automation systems. Do not apply

loop power to this probe. The system requires a two-wire power connection and separate two-wire connections

for each analog output. Analog signal outputs are isolated from power.

Figure 15: Primary Probe Wiring

1

Table 5: Primary Probe Features

Callout

Feature

Description

1

Reset

Cycles power to the device without unplugging it

preliminary—this information may change

TDP05K Advanced Thermal Dispersion Probe Airflow Measuring System Installation Instructions

12

Ruskin—CONFIDENTIAL

Wiring Connections

Primary Probe Wiring

BACnet® Output

1. Carefully remove the top of the Phoenix Contact screw terminal connector and insert the wires. Tighten the

terminals and reconnect them to the controller board.

2. Connect the BACnet® output (A- and B+) from the primary probe to a BACnet network.

IMPORTANT: Do not run the probe wiring in the same conduit as AC power wiring or with wiring used to supply

highly inductive loads, such as motors, contactors, and relays. Fluctuating, erratic, and inaccurate signal levels

are possible when AC power wiring is present in the same conduit as the signal lines. Run the wiring away from

variable frequency drives and broadcast antennas.

IMPORTANT: The primary probe provides two 4 to 20 mA signals to building automation systems. Do not apply

loop power to this probe. The system requires a two-wire power connection and separate two-wire connections

for each analog output. Analog signal outputs are isolated from power.

Figure 15: Primary Probe Wiring

Note: The two A- connections and the two B+ connections are electrically identical.”

preliminary—this information may change

TDP05K Advanced Thermal Dispersion Probe Airflow Measuring System Installation Instructions

12

Ruskin—CONFIDENTIAL

Wiring Connections

Primary Probe Wiring

Analog Output

1. Carefully remove the top of the Phoenix Contact® screw terminal connector and insert the wires. Tighten the

terminals and reconnect them to the controller board.

2. Connect the 4 to 20 mA analog flow output (A01: Pos and Com) and the 4 to 20 mA analog output factory

default temperature (A02: temperature output) from the primary probe to a building automation system.

Note: The factory default flow output is A01. Either output A01 or A02 can be configured for temperature or flow,

or both can be configured for temperature and flow.

Probe Network

Connect the Shield, D+, and D- from the primary to the ancillary probe or remote display using the approved

communications wire.

1. Carefully remove the top of the Phoenix Contact screw terminal connector and insert the wires. Tighten the

terminals and reconnect them to the controller board.

2. Connect the BACnet® output (A- and B+) from the primary probe to a BACnet network.

IMPORTANT: Do not run the probe wiring in the same conduit as AC power wiring or with wiring used to supply

highly inductive loads, such as motors, contactors, and relays. Fluctuating, erratic, and inaccurate signal levels

are possible when AC power wiring is present in the same conduit as the signal lines. Run the wiring away from

variable frequency drives and broadcast antennas.

IMPORTANT: The primary probe provides two 4 to 20 mA signals to building automation systems. Do not apply

loop power to this probe. The system requires a two-wire power connection and separate two-wire connections

for each analog output. Analog signal outputs are isolated from power.

Figure 15: Primary Probe Wiring

Airflow-IQ Start-up & Commissioning Guide

16

Analog Output

1. Carefully remove the top of the Phoenix Contact® screw terminal connector and insert the wires. Tighten the

terminals and reconnect them to the controller board.

2. Connect the 4 to 20 mA analog flow output (A01: Pos and Com) and the 4 to 20 mA analog output factory

default temperature (A02: temperature output) from the primary probe to a building automation system.

Note:

The factory default flow output is A01. Either output A01 or A02 can be configured for temperature or flow,

or both can be configured for temperature and flow.

Probe Network

Connect the Shield, D+, and D- from the primary to the ancillary probe or remote display using the approved

communications wire. A03 is not used at this time.

Note:

The two D- and D+ connections are electrically identical.

BACnet® Output

Table 5: Primary Probe Features

Callout

Feature

Description

1

Reset

Cycles power to the device without unplugging it