FOCUS 320 SBR Owner's Manual

22

RSF Woodburning Fireplaces

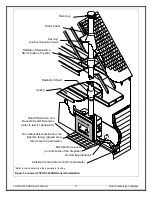

COVERING THE FIREPLACE FACING

Facing materials (see Figure 3 and Figure 4) MUST BE NON-COMBUSTIBLE such as metal, brick, slate or ceramic

tile. Gypsum board is NOT an acceptable facing material. Gypsum board cannot get closer to the fireplace than the

side and top standoffs.

Facing this fireplace can be as simple as using cement boards that will be painted or gluing ceramic tiles with high

temperature silicone sealant.

MANDATORY OPTIONS WITH THE CLEAN FACE

When installing a Clean Face (FO-F2) on your FOCUS 320 SBR, you MUST install the intake duct (part of FO-F2)

to provide sufficient air to the unit along with two Gravity Vent Kits (FO-V2 or FO-V3, sold separately) to provide an

evacuation path for the heat. Neglecting to install either one of these will result in overheating of the unit and may

put your safety at risk. Refer to each option's installation instructions for particular details.

Use only genuine RSF parts. The use of any substitutes will void the warranty and may put your safety at risk.

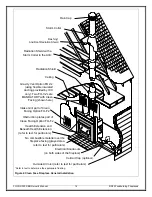

HEARTH EXTENSION

The area immediately in front of the fireplace must be protected by a non-combustible material such as brick, tile,

stone, or slate. Refer to Table 1 (G-H) for the depth and width that the hearth protection should extend beyond the

front and both sides of the door opening (see Figure 1). There is no minimum thickness required for the hearth

extension.

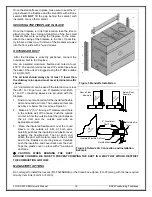

BENEATH HEARTH EXTENSION

If your fireplace is installed on a non-combustible

floor, the spark guard specified below is not required.

Install the spark guard provided (5" x 36" piece of

sheet metal) halfway under the fireplace and halfway

under the hearth extension and centered on the door

opening. The spark guard will extend 2½" beneath

the fireplace. This will make certain that sparks

cannot lodge in this area and start a fire. If necessary,

the provided spark guard can be cut to the minimum

width specified in Table 1 (I).

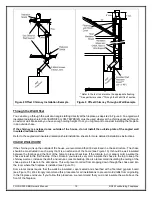

If you are preparing a raised installation, you will need a custom made spark guard, either a "Z" shaped spark guard

or a right angle spark guard (see Figure 13). The Z-shaped spark guard must be used if the height between the

bottom of the fireplace and the top of the non-combustible flooring of the hearth extension is less than or equal to

2 ½". The height of the Z-shaped spark guard must equal the distance between the floor and the base of the unit

and go under the hearth extension and the fireplace by at least 2½". If the unit is installed higher than 2 ½" from the

top of the flooring, a right-angle spark guard is necessary. The sides of the right-angle spark guard should be at

least 2½" x 2½" and must be covered with non-combustible material. Any custom made spark guard must have the

minimum width specified in Table 1 (I), and be installed centered on the door opening.

NOTE

: Custom-made spark guards are site built.

MANTEL

Masonry and other non-combustible mantels (shelf and posts) can be placed anywhere around the fireplace

opening, without blocking any of the bottom and top louvers. If the non-combustible mantel is located between the

top of the fireplace facing and the specified height for a combustible mantel, then the wall portion between the top

of the fireplace facing and the mantel must be covered in non-combustible material. If the non-combustible mantel

is located at the same height allowed for a combustible mantel, or higher, then no special wall covering is required

below the mantel.

For combustible mantels shelves, please see Table 1 (J-K) for the maximum depth of the mantel shelf and their

clearance requirements. See Figure 1 for an example.

Vertical mantel posts on the sides of the fireplace opening must be non-combustible. Combustible mantel posts are

not permitted unless they meet the clearance required to a perpendicular sidewall (see Table 1 (B)).

Figure 13 Special Custom-made Spark Guard

Non-

Combustible

Flooring

Right Angle

Spark Guard

(not provided)

More than 2 1/2"

Non-

Combustible

Flooring

Z-Shaped Spark

Guard (not

provided)

2 1/2" or less

RSF

Fireplace