After the head height has been set correctly, the clearance between the tops of the

blade assemblies,

(p5-3, item 6), and the

reset pad,

(p5-2, item 2), should be checked. To do this, run the head assembly

to the top of the stroke. Open the

pivoting guard,

(p5-1, item 1), and look for a space between the blade

assembles tops and the bottom of the reset pad. Hold onto each

retainer bar,

(p5-3, item 3), in turn and

try to move the head assembly

magnet carrier

within its’ mounting slot. The head should move around

easily without the blade assemblies touching the

reset pad.

There should be no greater clearance than

approximately .06 inches, (1.5 mm), between the tops of the blades and the reset pads.

To correct clearance add or delete shim washers between the top of the

reset plate studs,

(p5-2, item

16) and the reset plate. Shim washer numbers are:

•

11451009 ................................................. Washer, flat 3/4 id x .032 thk

•

11450116 ................................................. Washer, flat 3/4 id x .092 thk

There may already be washers on top of the reset posts to adjust the height of the reset plate. The 700M

is carefully adjusted at the factory. If, for any reason, the reset plate, head frame or guide frame is

removed from the machine, be sure to keep track where each shim washer goes. During reassemble,

make sure that the washers go back in exactly the same position.

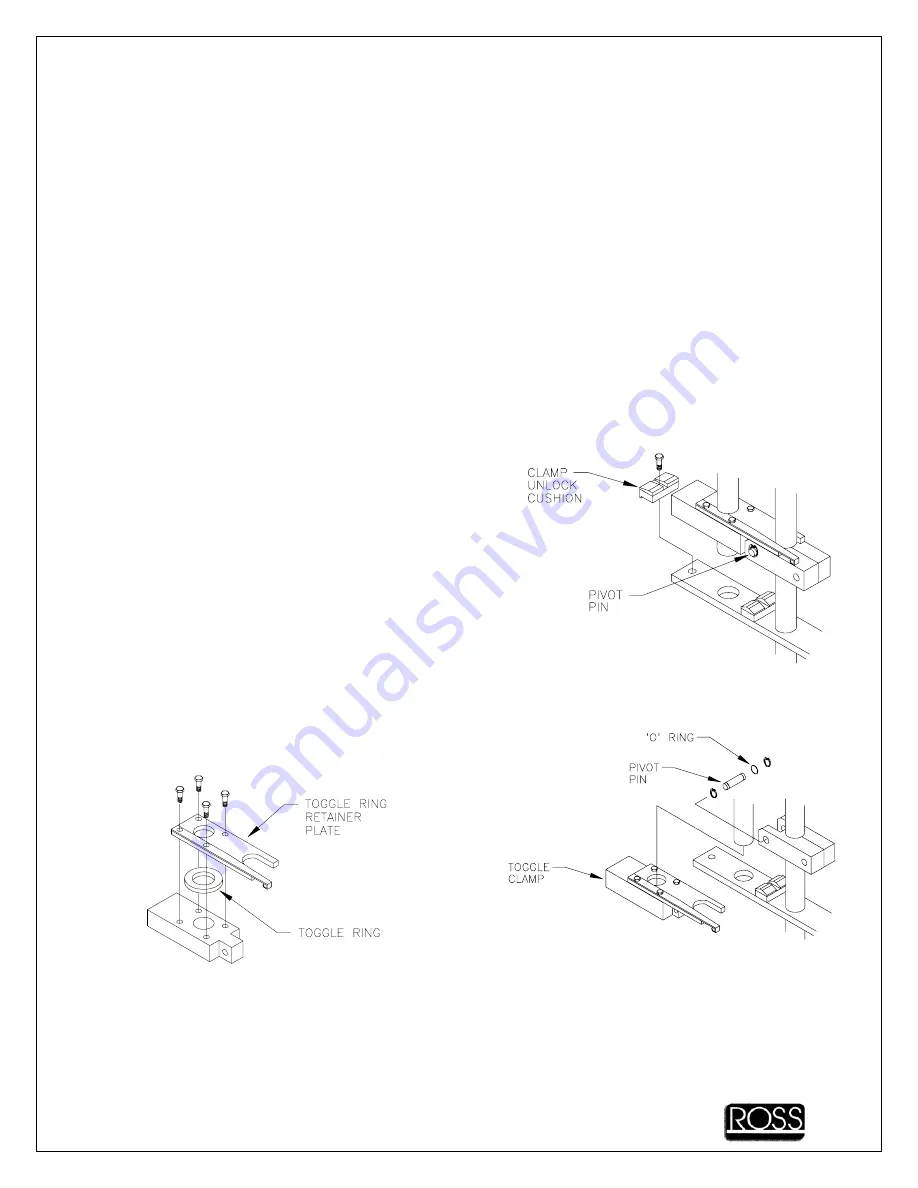

7.3.5 TOGGLE

RING

REPLACEMENT

A

. Disconnect the machine power cord. Remove the side

cover panel.

B

. Rotate motor coupling (in direction of arrow) until head

assembly is in full down position.

C

. Remove unlock cushion

D

. Remove pivot pin, turn toggle clamp and remove from

shaft

E

. Remove toggle ring retainer plate and toggle ring

F

. Install new toggle ring; replace toggle ring

retainer

plate.

NOTE

- Always install new toggle rings on both sides.

G

.

Replace toggle clamp. Install pivot pin

Make sure snap rings are in position

H

. Check the snap ring position on the guide uprights. There should be one snap ring above and one

below the clamp pivot, the snap rings go in the lower two grooves on the guide uprights

MN700-MC0010

7-5

Summary of Contents for TC700M

Page 2: ...MN700 MC0010 ...

Page 13: ...3 5 INSTALLATION CHART MN700 MC0010 3 4 ...

Page 17: ...5 2 HEAD CARRIER ASSEMBLY MN700 MC0010 5 2 ...

Page 18: ...5 3 HEAD ASSEMBLY MN700 MC0010 5 3 ...

Page 19: ...MN700 MC0010 5 4 5 4 CONVEYOR DRIVE ASSEMBLY ...

Page 20: ...MN700 MC0010 5 5 5 5 CONVEYOR ASSEMBLY ...

Page 21: ...5 6 MOTOR REDUCER ASSEMBLY MN700 MC0010 5 6 ...

Page 22: ...5 7 CAM DRIVE ASSEMBLY MN700 MC0010 5 7 ...

Page 23: ...MN700 MC0010 5 8 5 8 CAM ASSEMBLY ...

Page 25: ...5 10 TOGGLE CLAMP RETURN SPRING ASSEMBLY MN700 MC0010 5 10 ...

Page 26: ...5 11 MAIN FRAME ROCKER BAR CAM FOLLOWER MN700 MC0010 5 11 ...

Page 30: ...6 3 HEAD ASSEMBLY INSTALLATION MN700 MC0010 6 4 ...

Page 43: ...MN700 MC0010 9 1 9 WIRING SCHEMATIC ...

Page 44: ...MN700 MC0010 9 2 ...