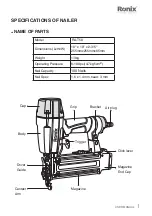

16 GAUGE 50MM FINISH NAILER

10

MAINTENANCE CHART & OPERATOR TROUBLESHOOTING

.

MAINTENANCE CHART

.

OPERATOR TROUBLESHOOTING

Practice

Reason

Method

Drain air line filter daily

Prevent accumulation of

moisture and dirt.

Open manual petcock.

Keep lubricator filled.

Keep the tool lubricated

Fill with RONIX

SERVICE pneumatic tool

lubricant.

Clean magazine and

feeder mechanism.

Prevent a jam & Dry fire.

Blow clean daily.

Lubricate the Tool after

nailing.

Extend the tool life.

Supply 3~4 drops of lubricant into the tool.

Drain air compressor.

Keep the tool operated

properly.

Open petcock on air compressor tank.

Problem

Check Method

Correction

Tool operates,

but no nail is

driven.

Check air pressure.

Reduce air pressure. (58~100psi)

Check for a jam.

Clean a jam. (Refer to 4-1)

Check for proper nail.

Use only recommended nails.

Tool operates,

but no nail is

driven.

Check air line & Plug

Check for air line connection and damage

to fitting part (Change it in case of damage)

Check for abnormality in head valve

Change O-ring in case of damage

Check air pressure.

Reduce air pressure. (58~100psi)

Check position Piston set

Readjust.

-

Supply of lubricant into the tool.

Driver blade worn or damaged?

Part change (Contact RONIX

SERVICE or

Distributor)

Piston O-ring worn or damaged?

-

Check air pressure.

Reduce air pressure. (58~100psi)

Check air pressure.

Reduce air pressure. (58~100psi)

Check for proper nail.

Use only recommended nails.

-

Supply of lubricant into the tool.

Piston O-ring cut or heavily worn?

Part change. (Contact RONIX SERVICE or

Distributor)

Check air pressure.

Reduce air pressure. (58~100psi)

Check inside diameter of air hose.

Use larger air hose.