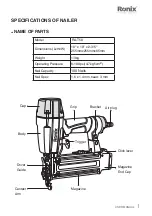

16 GAUGE 50MM FINISH NAILER

6

INSTRUCTIONS FOR OPERATION

.

BE SURE TO READ THE SAFETY INSTRUCTION BEFORE USING

THIS TOOL

.

PREPARATIONS

1) Be sure to put on personal protective equipment for example

goggles, earplugs, safety cap before using this tool.

2) Be sure to use an air compressor authorized by the safety certifi

-

cation author ity as a pressure source for operating this tool within the

optimum range of pressure (58~100psi).

3) Make sure that this tool has no trouble about the safety device, the

trigger, fasteners such as bolts, and so on.

4) Inject three or four drops of oil used exclusively for a tool into the air

plug before using this tool. (Do this regularly once a day if possible.)

5) Check the airline and the air connector for damage and Don’t use

longer airline than necessary (over 17ft).

PRELIMINARY CHECKUP

1) To give a checkup to the tool, adjust the operating pressure to 58 psi

(4 bar) before air connection.

2) Keep pressure low as far as it may cause no trouble in operation

within the optimum range of pressure according to hardness of the

working plane and length of fasteners.

LOADING NAILS

WARNING!

Turn the muzzle downward and never pull the trigger in loading or

unloading nails.

1) Pull the magazine backward with the click lever pressed.