3. Assembly and Ink Filling

13

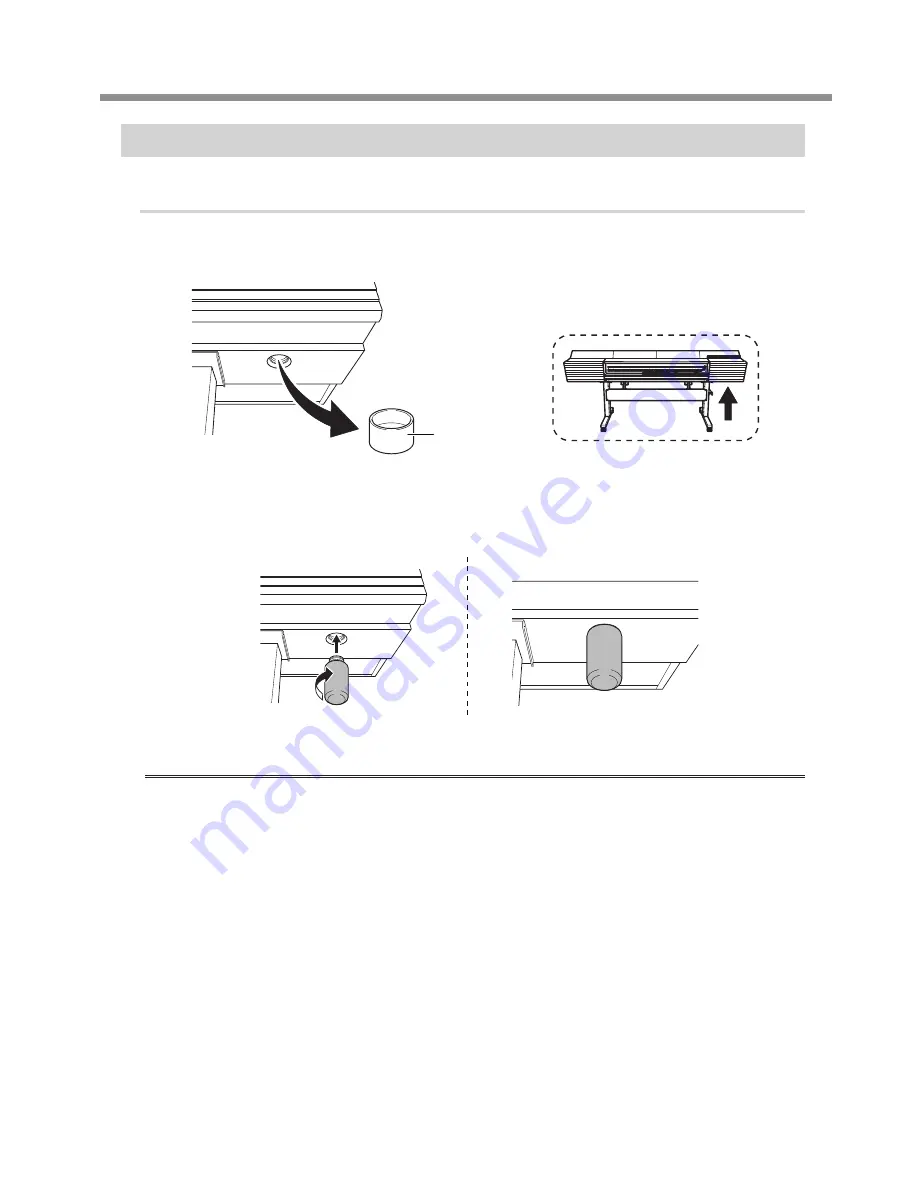

Step 3 : Installing the Drain Bottle

Procedure

A

Remove the bottom plug.

Use caution, because discharged fluid used in the inspection when the printer was shipped may remain.

Bottom plug

B

Install the drain bottle.

Screw the drain bottle into the hole where the bottom plug was attached. Use caution to turn the bottle

without applying excessive force.

Leave the drain bottle attached at all times.

Only remove the drain bottle when you are disposing of the discharged fluid. Unnecessarily removing the

drain bottle may lead to the discharged fluid spilling.