Technical

Training

Guide

C)

Mission

Control

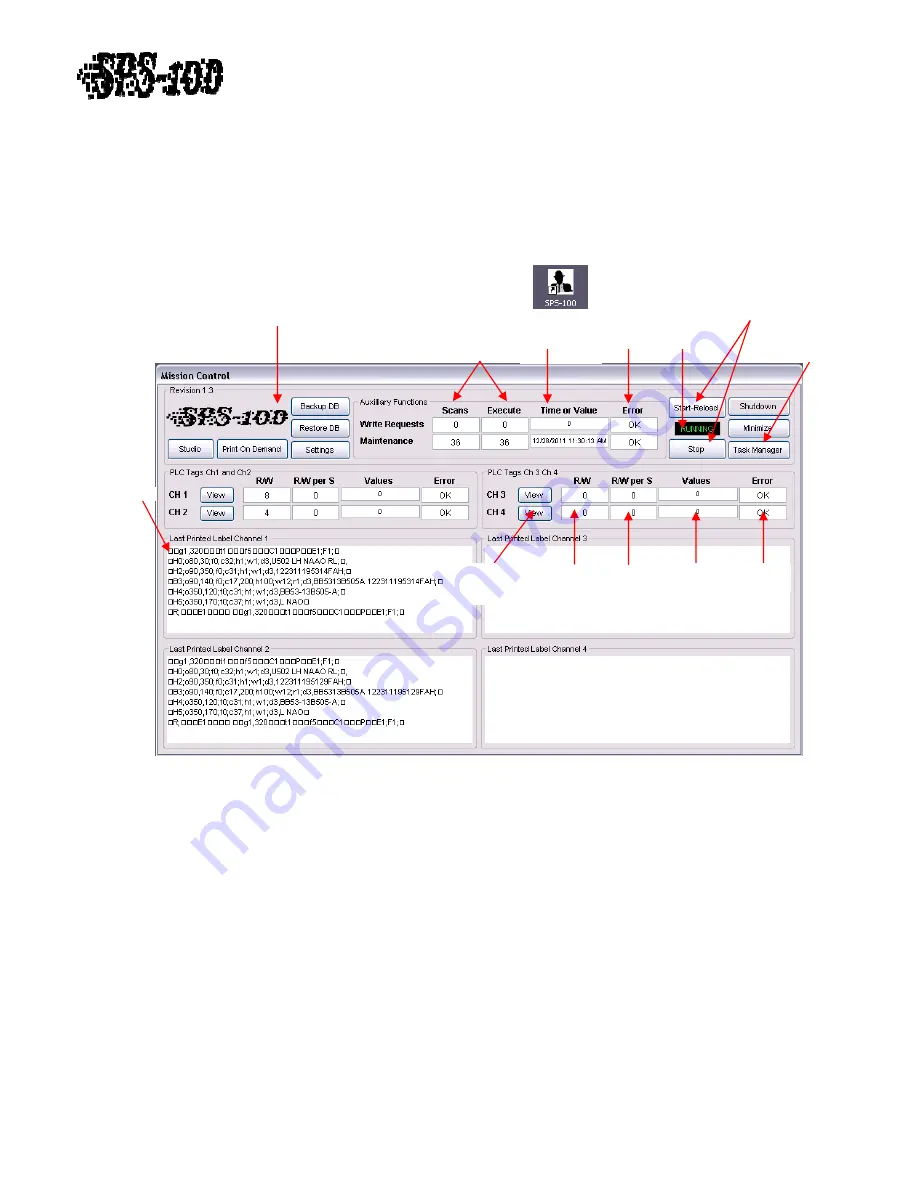

Figure

15

Mission

Control

is

the

application

that

monitors

changes

in

trigger

and

label

numbers

from

the

PLC

and

sends

applicable

label

strings

to

each

printer

when

triggered.

This

application

must

be

running

at

all

times.

Anytime

a

configuration

or

PLC

Address

change

is

made,

Mission

Control

will

need

to

be

restarted.

If

Mission

Control

is

inadvertently

or

purposely

shutdown

it

can

be

restarted

by

double

clicking

the

desktop

icon

shown

in

Figure

15.

Figure

16

Start

and

Stop

OPC

Reading

and

Writing

Number

of

Times

Ran

and

Successful

Executions

Enable/Disable

Windows

Task

Manager

Click

to

View

PLC

Values

Total

Hourly

OPC

Reads

OPC

Error

Last

Value

Read

OPC

Reads

Per

Second

Status

Error

during

Execution

Last

attempted

Time

Stamp

Function

Buttons

Last

Printed

Label

Status

The

Status

text

box

displays

whether

Mission

Control

is

running

or

not.

Green

“Running”

text

displays

when

PLC

scanning

is

occurring

and

red

“Stopped”

text

displays

when

PLC

scanning

is

not

occurring.

Left

click

the

Stop

Button

to

stop

PLC

scanning

and

left

click

the

Start

‐

Reload

Button

to

start

or

restart

PLC

scanning.

Left

click

the

Shutdown

Button

to

shutdown

Mission

Control

.

Labels

will

not

automatically

unless

Mission

Control

is

started

and

PLC

Scanning

is

“Running”.

Shutting

down

Mission

Control

and/or

stopping

PLC

scanning

requires

the

system

password

to

be

entered.

(See

Figure

16)

PLC

Tag

Values

PLC

tag

values

can

be

monitored

and

viewed

for

troubleshooting

purposes.

Any

changes

in

values

of

the

Trigger

or

Label

Number

value

is

recorded

in

the

R/W

(Read/Write)

and

the

R/W

per

S

(Read/Write

per

Second)

text

boxes.

The

actual

value

recorded

is

shown

in

the

Values

text

box

and

any

PLC

addressing

errors

will

be

displayed

by

red

“Error”

text

in

the

Error

text

box.

Use

these

values

for

quick

troubleshooting.

If

all

values

are

zero,

no

values

are

displayed

or

there

is

red

“Error”

text

in

Revision

1.0

‐

7

of

15