First start-up

44

5

ignition request is disabled. The regular operation of the

boiler is allowed only when the operation is completed.

To check and calibrate the CO

2

value at maximum and minimum

power, proceed as follows, referring to Figure 5.9

The CO

2

values and other parameters useful to verify combus-

tion are summarized in Table 5.5

▶

Power the boiler.

▶

Open the gas valve on the boiler and check that the valves

connecting to the system are open.

▶

Activate the heating request to the boiler, through the con-

trol devices provided, and provide an adequate thermal load

for carrying out the verification operations.

▶

Insert the flue gas analyser into the flue gas analyser socket

and turn it on.

For the Caldaria 35 and Caldaria 55.1 models, the flue gas

analysis socket is positioned on the flanged socket (de-

tail PF, Figure 5.10

p. 44), or on the optional rainproof

terminal (code OTRM031).

If you want to use the flue gas analysis socket positioned

on the flanged socket, to access the socket it is necessary

to remove the upper flange and the upper casing of the

boiler (Paragraph 5.2

For the Caldaria 100.2 model, the flue gas analysis socket

must be provided on the flue gas exhaust pipe. It is al-

ready provided on the rainproof terminal, available as

optional OTRM009.

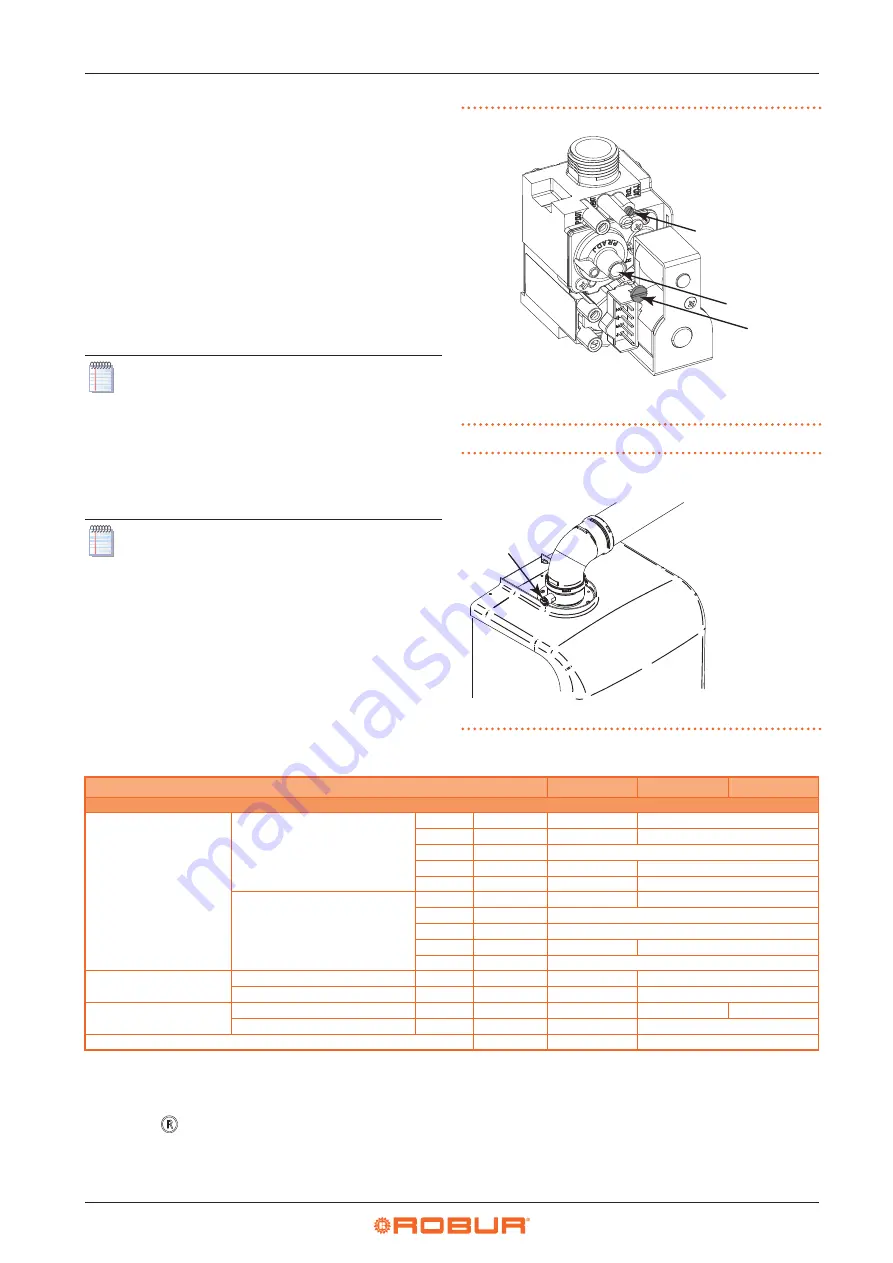

Figure 5.9

Gas valve

A

Protection screw

1

Gas flow adjustment screw

2

Offset adjustment screw

1

2

A

Figure 5.10

Socket for flue gas analysis for Caldaria 35 and 55.1

PF

Flue gas

analysis socket

PF

Table 5.5

Caldaria combustion parameters

Caldaria 35

Caldaria 55.1

Caldaria 100.2

Installation data

CO

2

percentage in fumes

Nominal heat input

G20

%

9,45 ÷ 9,25

9,3 ÷ 9,1

G25

%

9,35 ÷ 9,15

9,3 ÷ 9,1

G25.3

%

9,3 ÷ 9,1

G30

%

11,4 ÷ 11,2

11,3 ÷ 11,1

G31

%

10,55 ÷ 10,35

10,3 ÷ 10,1

Minimal heat input

G20

%

9,05 ÷ 8,85

9,0 ÷ 8,8

G25

%

9,0 ÷ 8,8

G25.3

%

9,0 ÷ 8,8

G30

%

10,75 ÷ 10,55

10,9 ÷ 10,7

G31

%

9,9 ÷ 9,7

Flue temperature

Nominal heat input

G20

°C

69,4

66,4

Minimal heat input

G20

°C

61,3

56,8

Fumes flow rate

Nominal heat input

G20

kg/h

54

80

161

Minimal heat input

G20

kg/h

7

8

CO emission

ppm

75,0

68,0

5.5.1

Minimum heating power

1. Activate the chimney sweep function by pressing for 7 sec-

onds the

key (Figure 6.1

p. 47). The maximum time be-

fore being forced out of the function is 15 minutes.

2. Check that the CO

2

value conforms to that reported in Table

5.5

3. If this is not the case, unscrew the protection screw A and ad-

just with a 4 hex key the screw 2 of the offset adjuster (Figure

5.9

p. 44). To increase the value of CO

2

turn the screw

clockwise and vice-versa if you want to decrease it.

4. Once completed the adjustment, tighten the protection

screw A on the offset adjuster.

Summary of Contents for Caldaria 100.2 Condensing+ export

Page 55: ......