7

GB

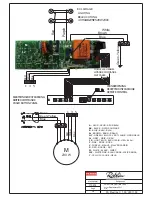

markings identifying the terminals in your plug, proceed as follows.

- The wire which is coloured green and yellow must be connected to the terminal in the plug which is

marked with the letter

E

or by the earth symbol or coloured green or green and yellow.

- The wire which is coloured blue must be connected to the terminal which is marked with the letter

N

or

coloured black.

- The wire which is coloured brown must be connected to the terminal which is marked with the letter

L

or

coloured red.

ATTENTION: Do not forget to use adequate plugs to the support brackets. Enquire after the manu-

facturers. Do an embedding if necessary. The manufacturer accepts no responsibility in case of a

faulty hanging due to the drilling and the setting up of plugs.

GB

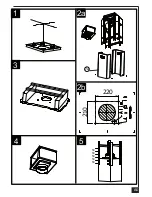

1) Unpack the hood parcel (

A4 & A5

). To remove the cap of the lower chimney and to disconnect the

control.

• LAYING OUT BEFORE FITTING THE HOOD

2) Mark the centre of the cooking appliance onto the ceiling with a plumb line. Draw the horizontal axes

running parallel to the stove top onto the ceiling as illustrated

Fig. 1

.

3) Place the drill gauge centred on the axes aligning the axes on the drill gauge centrally over these

axes as illustrated

Fig. 2b

.

4) Remove the self-tapping screws, which fix the chimney

item 7

to the metal frame bracket as illustrated

in

Fig. 2a

and then remove both sides of the upper chimney stacks.

•

FITTING THE CANOPY BRACKET

5) Mark the positions on the ceiling for : - The cut-out for the ducting Ø 150 mm in the extraction

mode and Ø 200 mm in the remote mode when ducting runs through the ceiling.

- The mains supply cords.

- The 4 fixing holes for Ø 10 mm nuts and bolts.

Drill the different holes with the appropriate masonry bit. When fixing the cooker hood to a plasterboard

ceiling ensure it is reinforced as illustrated in

Fig. 3

and attach using four Ø10mm nuts and bolts; ensuring

the bolts as sleeved between the plasterboard and the joist supports to prevent the ceiling being damaged

when the bolts are tightened up.

If the ceiling is concrete, use eight Ø 10 mm steel rawl bolts. Plastic rawl plugs must not be used.

6) Remove the deflector

Fig. 4

.

7) The height of the cooker hood can be adjusted in 50 mm stages. 650 mm when fitting above an

electric hotplate and 700 mm when fitting above a gas hotplate. Select the height required using the

measurements illustrated in

Fig. 5

& 6

and fix the metal diffuser to the frame of the chimney brackets

using the height 5 x 10T hexagonal headed screws. A drawing on the drill gauge defines the positioning

for the controls.

Attention: 2 persons are necessary to secure this operation.

8) Check the vertical of the chimney.

• DUCTING

The hood is more effective when used in the extraction mode (ducted to the outside). When the cooker

hood is ducted to the outside, charcoal filters are not required.

The ducting used must be 150 mm (6 INS), rigid circular pipe and must be manufactured from fire retard-

ant material, produced to BS.476 or DIN 4102-B1. Wherever possible utilise rigid circular pipe which has

a smooth interior, rather than the expanding concertina type ducting.

Maximum length of ducting run:

- 4 metres with 1 x 90° bend.

- 3 metres with 2 x 90° bends.

- 2 metres with 3 x 90° bends.

The above assumes our 150 mm (6 INS) ducting is being installed. Please note ducting components and

ducting kits are optional accessories and have to be ordered, they are not automatically supplied with the

chimney hood.

Summary of Contents for Escale 2 centrale 900

Page 17: ...A4 5 6 Composants Components Bauelemente Componenti Componentes Onderdelen R 7 8...

Page 18: ...A5 Colis Hotte Hood Parcel 1 2 4 3...

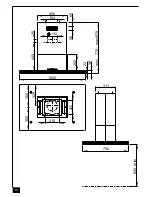

Page 19: ...A6 2a 7a 1 3 4 5 2b 220 210 50 50 50 50 50...

Page 20: ...A7 6a 6b 6c 7a...

Page 21: ...A8 7b 6c 2 1 2 3 2 2 1 3 2...

Page 22: ...A9 A 6d C 6 7...

Page 23: ...A10 8 9 7b 2 1 2 3 2 2 1 3 2...

Page 24: ...A11 10 11...

Page 27: ...A14 GU10 28 W 230 V Code 12EC024 3 4...

Page 29: ......

Page 30: ......

Page 31: ......