Instruction Manual IM‐116

CUSTOMER'S INFORMATION BOX

CONTENTS ARE INDEPENDENT OF RIVERHAWK DOCUMENT CONTROL

215 Clinton Road

New Hartford, NY 13413

Tel: +1 315 768 4855

Fax: +1 315 768 4941

Email: [email protected]

REV

373A4028

GE DRAWING NUMBER

Revision H

Page 14 of 29

Flange Position

Stud Size

50% Pressure

50% Stretch

Turbine to Coupling

2.784"

[71 mm]

9000 psi

[620 bar]

Do not measure

Do not use

Coupling to Generator

2.283"

[58 mm]

10000 psi

[690 bar]

Do not measure

Do not use

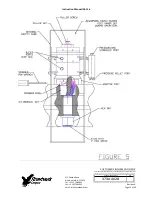

9.1.1 Tightening the Turbine/Coupling and Coupling/Generator Nuts

Turn the cylindrical nut using the spanner ring and pin wrench as depicted in Figure 5 until it

bottoms on the flange.

9.2 Removing the Tensioner from an Installed Stud

Puller tool removal is to accomplished as follows:

1.

Release the puller tool pressure by opening the valve on the pump. Leave the valve

open. This is automatic on the air‐operated hydraulic pump.

2.

Unscrew the puller screw using a wrench

3.

Tapping the wrench with a hammer may be necessary to loosen the puller screw.

4.

Move the tool to the next stud/nut assembly to be tensioned, following the

sequence/pattern as defined on the supplied data sheets.

9.3 Tensioning at Final Pressure

Repeat the pulling and tightening procedure stated above at full pressure. Measures the length

of the studs after all have been tensioned. The final pressure and required stretch values are

listed in the following table

Flange Position

Stud Size

Final Pressure

Final Stretch

Turbine to Coupling

2.784"

[71 mm]

18000 psi

[1170 bar]

0.011" ‐ 0.014"

[0.28 mm ‐ 0.36 mm]

Coupling to Generator

2.283"

[58 mm]

20500 psi

[1240 bar]

0.019" ‐ 0.023"

[0.48 mm ‐ 0.58 mm]