Instruction Manual IM‐116

CUSTOMER'S INFORMATION BOX

CONTENTS ARE INDEPENDENT OF RIVERHAWK DOCUMENT CONTROL

215 Clinton Road

New Hartford, NY 13413

Tel: +1 315 768 4855

Fax: +1 315 768 4941

Email: [email protected]

REV

373A4028

GE DRAWING NUMBER

Revision H

Page 6 of 29

□

Use the pin wrench in spanner ring to tighten nut.

□

Release pressure, move to next stud in pattern.

□

Repeat above steps at final pressure.

□

Measure final stud length and record on stretch datasheets. Calculate stretch.

□

Torque nuts' set screws.

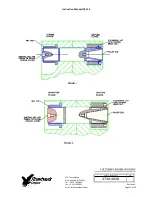

Detensioning (Stud removal)

□

Loosen nuts' set screws

□

Inspect and clean studs' conical threads.

Do not continue until ALL debris is removed

from the threads!

Do not try to use the tensioner to remove a damaged stud!

□

Apply a light coat of clean turbine oil or spray lubricant to the puller screw.

DO NOT USE

“NEVER SEIZE” ON THE CONICAL THREADS.

□

Slide spanner ring over the puller screw.

□

Mount the tensioner on the stud.

□

Install spanner ring into nut.

□

Tighten the puller screw.

□

Back off puller screw 1/2 a turn.

□

Retighten the puller screw and leave tight.

DO NOT BACK OFF PULLER SCREW.

□

Bleed the tensioner.

Do NOT bleed tensioner off of a stud! Damage to the tool will

result!

□

Apply final pressure.