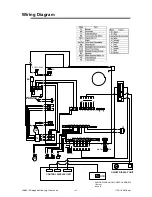

RIB2312 Sapphire Gas Log Flame Fire

- 9 -

1/03/18 ©Rinnai

Fault Analysis

Electrical Component Analysis

Note:

Before starting inspection, check wiring and double check all connectors are tight

Before carrying out checks marked*, remove power cord from socket

Nature of

fault

Examination point

Diagnostic point

Values

Actions

A. Burner will

not light

(1) Is the voltage

correct

Check power point and

voltage

AC216 ~ 264V Ensure power cord is plugged

in and turned on

Check that power is supplied

to control panel

Ensure manual control panel is

turned ON

(2) Is the 3A fuse in the

power supply OK

* measure the resistance

of the fuse

<1

Replace if blown

(3) Over Heat Switch

open circuit, faulty or

OHS connector

disconnected

(unit sparks for 2

seconds then stops)

*Measure the resistance of

the switch

<1

With power supply off

check

that OHS continuity is <1

OHS switch activation caused

by insufficient flue draw

Check if OHS lead is correctly

connected to Ignition pack

(4) Is there voltage to

the ignition pack

With the appliance

switched on check for

voltage at the ignition pack

AC216 ~ 264V

B. No spark at

Ignition probe

(5) Loose high tension

lead or cracked/

damaged ignition

probe

Check by visual

observation that spark is

between electrode and

Pilot head (gap 3.5mm ±

0.5)

C. Ignition

occurs but fire

pilot does not

light

(6) Check gas

pressure at test point

Check gas pressure with

digital manometer

See data plate

(7) Check Voltage at

POV

Yellow Yellow

POV terminals

DC12V

75 ~ 85

D. Pilot lights

but goes out

after 1 minute

(8) Check flame rod

current

Check on flame rod testing

connection plug

>15mA

E. Fire lights but

flame does not

modulate

(9) Check voltage to

POV

Yellow Yellow

POV terminals

DC12V

75 ~ 85

F. Fan does not

come on

(10) Check voltage at

fan motor

HI Fan

Blue-White

LO Fan

Yellow - White

AC110 ~ 130V

AC110 ~ 130V

(11) Check resistance

at fan motor

HI Fan

Blue-White

Lo fan

Yellow - White

170~190

240~260