- 20 -

10 Maintenance

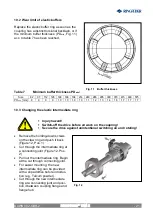

The elastic coupling

RINGFEDER

®

TNM G

has in operation a low-maintenance.

Reaching the wear limit of the elastic intermediate ring depends on the operating parameters

and the conditions of use.

In the case of routine monitoring work on the plant check:

Alignment of the coupling

Elastomer state

Remove dust deposits from the coupling parts and the intermediate ring

10.1

Wear Inspection on the Buffer Ring

Danger of injuries!

Disconnect the drive before carrying out any work on the

coupling!

Secure the drive against unintentional switching on and rotating!

Perform a visual inspection and a wear inspection of the buffer ring after

2000 hours, or after 3 months at latest, after the first start-up of the equip-

ment. If only minor wear or no wear is observed, further inspections of the

plant can be carried out at regular intervals of 4000 hours, however, at

least once a year, if the operating modes and conditions of the plant

remain unchanged. However, should you observe excessive wear on the

occasion of this first inspection already, check whether the cause for the

problem is listed in table 5 “Operation faults and possible causes”. In such

a case, the inspection intervals must be adapted to the prevailing service

conditions.

On the occasion of routine inspections or maintenance work on the drive equipment, or after

3 years at latest:

Replace the elastic buffer ring.

If the wear limit has been reached or exceeded, replace the buffer ring immediately,

irrespective of the inspection intervals of the equipment.

Check the alignment of the coupling.

Remove dust deposits from the coupling components and buffer ring.

RINGFEDER

®

TNM E

BAWN 002-GBR-2