DFT 250 (02)

DFT 250 (09)

DFT 250 (02)

DFT 250 (19)

���

���

���

���

O

S

L

W

1

O

S

L

W

2

F

F

F

E

F

E

E

D

E

F

F

A

B

F

F

B

A

E

E

D

P

a

c

P

Q

Q

T

Q

Q

Q

T

L

N

M

Q

L

N

M

B

F

F

A

a

c

e

Q

Q

e

Q

W

2

T

1

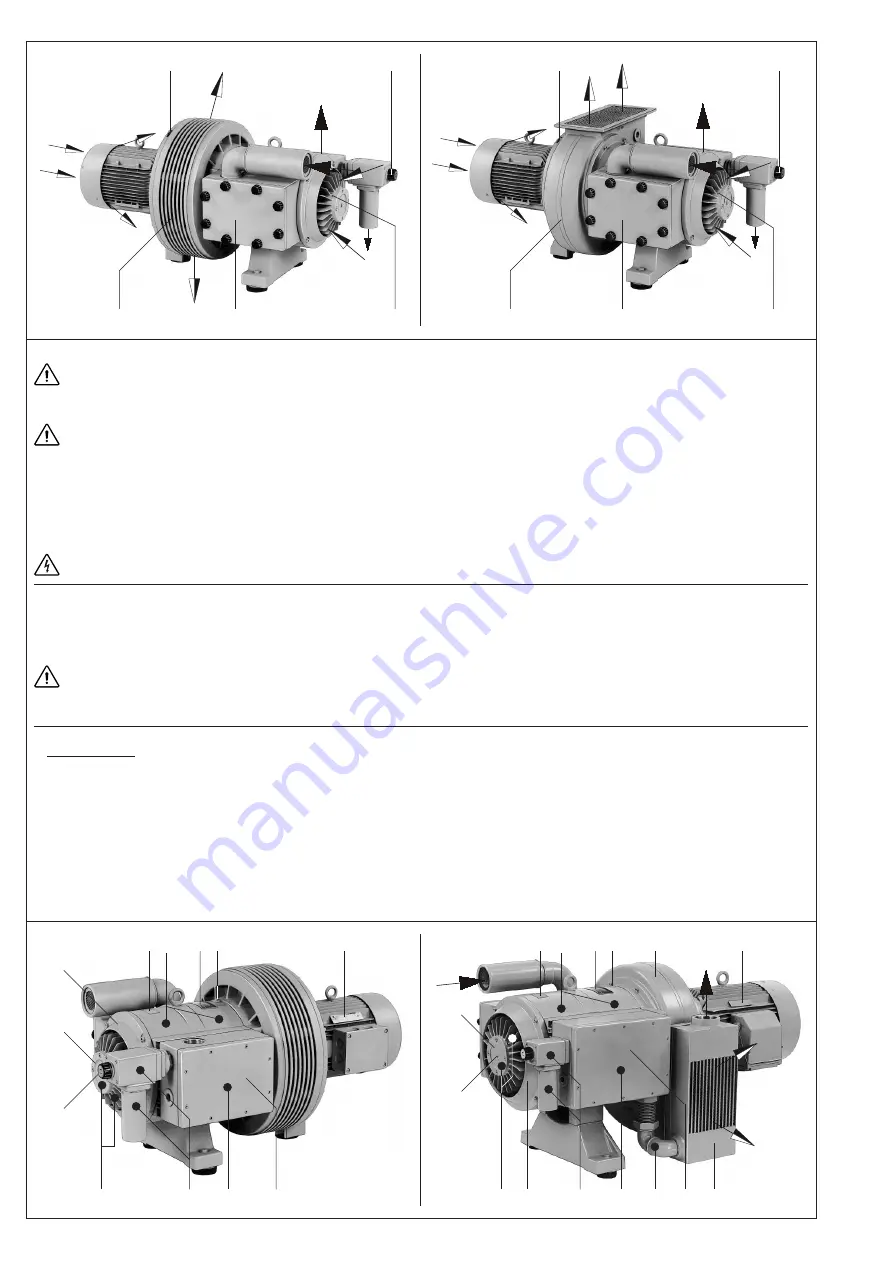

Installation (pictures

���

to

���

)

These compressors may not be operated without the standard pressure regulating and limiting valves fitted so that the maximum

pressure is not exceeded (see data plate).

For operating and installation follow any relevant national standards that are in operation.

1. Pressure connection at (B).

Long and/or small bore pipework should be avoided as this tends to reduce the capacity of the compressor.

2. The electrical data can be found on the data plate (N) or the motor data plate. The motors correspond to DIN/VDE 0530 and have IP 54

protection and insulation class B or F. The connection diagram can be found in the terminal box on the motor (unless a special plug connection

is fitted). Check the electrical data of the motor for compatibility with your available supply (voltage, frequency, permissible current etc.).

3. Connect the motor via a motor starter. It is advisable to use thermal overload motor starters to protect the motor and wiring. All cabling used

on starters should be secured with good quality cable clamps.

We recommend that motor starters should be used that are fitted with a time delayed trip resulting from running beyond the amperage setting.

When the unit is started cold, overamperage may occur for a short time.

The electrical installation may only be made by a qualified electrician under the observance of EN 60204. The main switch must

be provided by the operator.

Initial Operation (pictures

���

to

���

)

1. Initially switch the compressor on and off for a few seconds to check the direction of rotation against the direction arrow (O).

Note: On this initial start the pressure pipework should not be connected. If the compressor runs backwards with the pipework

connected a pressure could build up within the housing which could result in damaged rotor blades.

2. Connect the pressure pipe at (B).

For pipe work longer than 3 m we recommend using non-return-valves (ZRK), to avoid reverse rotation when the units are switched

off.

3. The required pressure ranges can be adjusted by turning the pressure regulating valve (D) according to the symbols on the top of the regulating

valve.

Potential risks for operating personnel

Noise Emission: The worst noise levels considering direction and intensity (sound power), measured according to DIN 45635 part 3 (as per

3. GSGV), are shown in the table at the back. When working permanently in the vicinity of an operating compressor we recommend wearing

ear protection to avoid any damage to hearing.