20085953

32

GB

Start-up, calibration and operation of the burner

6.5.3

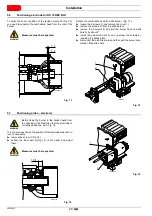

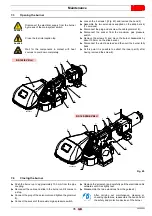

Minimum gas pressure switch

Adjust the minimum gas pressure switch (Fig. 37) after having

performed all other burner adjustments with the pressure switch

set to the start of the scale.

With the burner operating at maximum output, increase adjust-

ment pressure by slowly turning the relative knob clockwise until

the burner locks out.

Then turn the knob anticlockwise by 2 mbar and repeat the burn-

er start-up to ensure it is regular.

If the burner locks out again, turn the knob anticlockwise again by

1 mbar.

6.5.4

PVP pressure switch kit

Adjust the pressure switch for the valve leak detection control de-

vice (PVP Kit), if present, according to the instructions supplied

with the Kit itself.

6.6

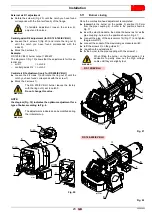

Steady-state operation

Burner without modulating operation kit

Once the start-up cycle is completed, the servomotor command

moves on to the thermostat/pressure switch TR that controls the

pressure or the temperature in the boiler.

If the temperature or the pressure is low (so the thermostat/

pressure switch TR is closed), the burner progressively

increases the output as far as the MAX value (point “P9”).

If the temperature or the pressure increases as far as the

opening of the thermostat/pressure switch TR, the burner

progressively reduces the output as far as the MIN value

(point “P1”). And so on.

The burner switches off when the request for heat is lower

than the heat supplied by the burner at MIN output.

The thermostat/pressure switch TL opens and the control

box carries out the switching off phase.

The damper closes completely to reduce thermal disper-

sions to a minimum.

Burner with modulating operation kit

See the manual supplied with the regulator.

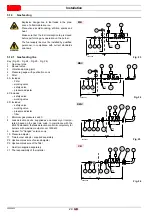

6.7

Ignition failure

If the burner does not switch on, there is a lockout within 3s of the

electrical supply reaching the gas valve.

It may be that the gas does not arrive at the combustion head

within the safety time of 3 s.

In this case, increase gas delivery upon ignition.

The arrival of the gas at the pipe coupling is shown on the pres-

sure gauge of Fig. 38.

6.8

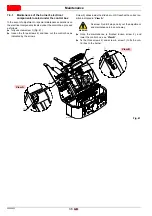

Checking the air and gas pressure on the combustion head

To check the air and gas pressure on the combustion head it is

necessary to connect the pressure gauges as shown in Fig. 38.

Fig. 37

D3855

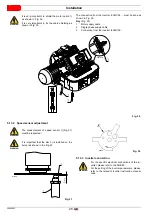

WARNING

In the event of a burner lockout, more than two

consecutive burner reset operations could cause

damage to the installation. On the third lockout,

contact the Aftersales Service.

DANGER

If further lockouts or burner faults occur, interven-

tions must only be made by qualified, authorised

personnel (as indicated in this manual, and in

compliance with the laws and regulations current-

ly in force).

20082133

Checking

gas pressure

Checking

air pressure

Fig. 38

Summary of Contents for RS 120/EV BLU

Page 2: ...Translation of the original instructions ...

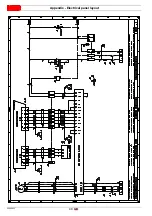

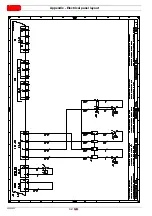

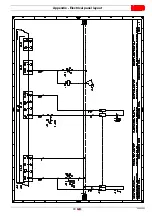

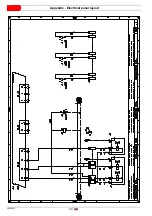

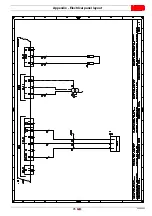

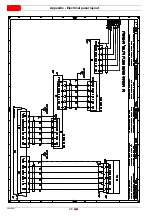

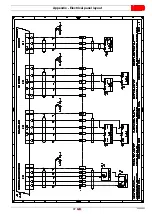

Page 43: ...41 20085953 GB Appendix Electrical panel layout ...

Page 45: ...43 20085953 GB Appendix Electrical panel layout ...

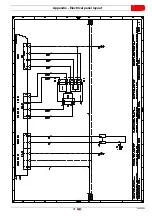

Page 46: ...20085953 44 GB Appendix Electrical panel layout ...

Page 47: ...45 20085953 GB Appendix Electrical panel layout ...

Page 54: ......

Page 55: ......