14

INStAllAtION

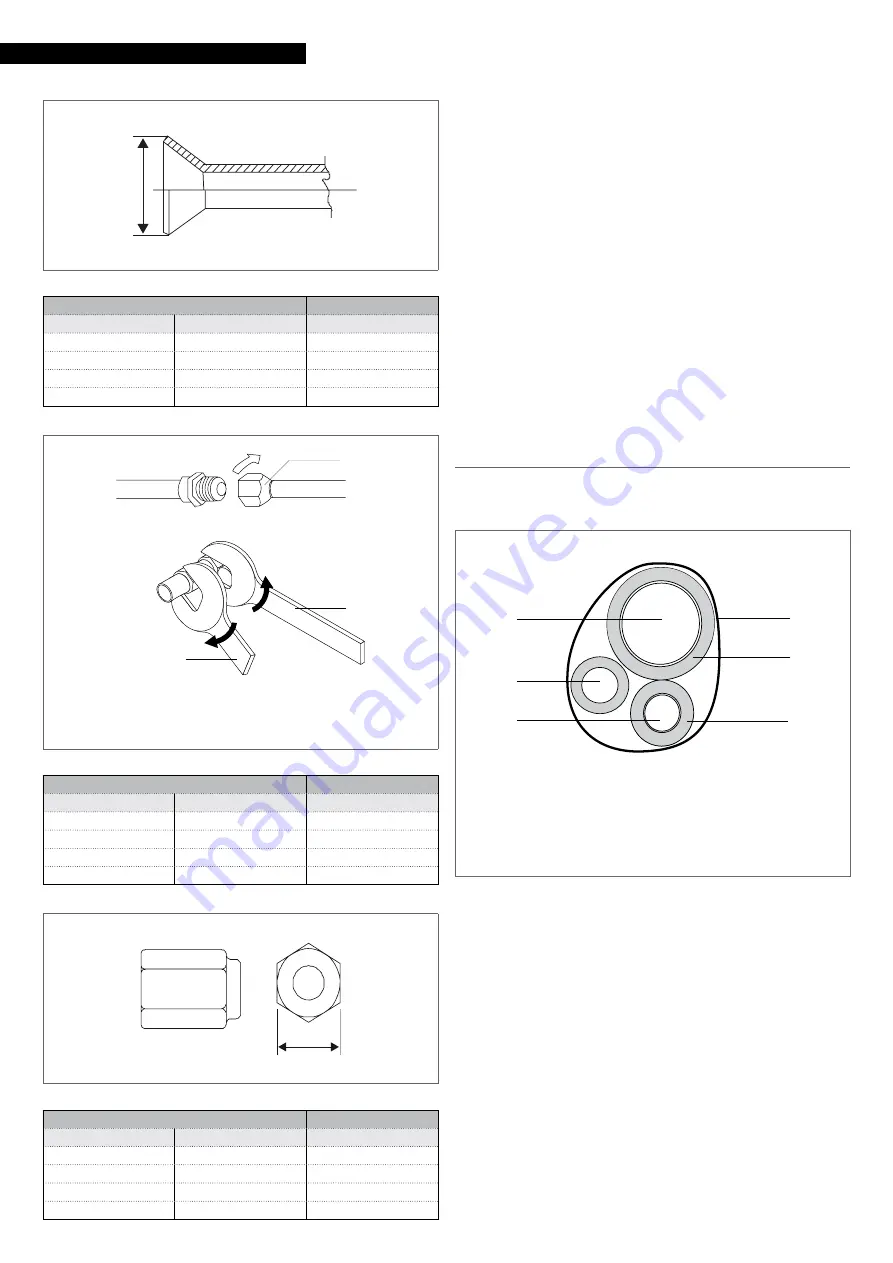

A

Pipe Ø

A

mm

inches

mm

6,35

1/4

9,1

9,52

3/8

13,2

12,70

1/2

16,6

15,88

5/8

19,7

1

Key

2

Torque wrench

3

Flare nut

2

3

1

Pipe Ø

tightening torque

mm

inches

Nm

6,35

1/4

18

9,52

3/8

42

12,70

1/2

55

15,88

5/8

60

A

Pipe Ø

A

mm

inches

mm

6,35

1/4

17

9,52

3/8

22

12,70

1/2

26

15,88

5/8

29

—

bring line ends with flare connection close to their cou-

pling on the unit

—

manually rotate the flare nuts by 3 - 4 turns

—

tighten the connections using a spanner and a counter

spanner

9

Use a torque wrench to tighten so as to prevent damage to

flare nuts and gas leaks.

9

Use equipment suitable for the system refrigerant.

9

Avoid using the refrigerant oil on the external part of the

flaring.

9

Avoid proximity to sources of ignition in continuous op-

eration (open flames, gas household appliances, electric

stoves, etc.).

9

As for circuit leak and pneumatic vacuum tests, refer to the

matching outdoor unit instruction booklet for the installer.

Pipe insulation

Connection pipes must be thermally insulated to prevent dis-

persions of heat or formation of condensate.

1

Gas pipe

2

Condensation discharge

3

Liquid pipe

4

Heat insulation

5

Adhesive tape

5

4

4

1

2

3

—

insulate the liquid and gas pipes separately

—

use insulating material that is thicker than 15 mm

—

ensure that the insulating material adheres to the pipe

without gaps

—

fix using adhesive tape

9

Do not tighten the adhesive tape too much, so as to avoid

damaging the insulation.

9

Avoid partial insulation of the pipes.

9

In case of use with outdoor temperature above 30 °C and

relative humidity above 80%, increase wall thickness up to

20 mm.

For gas pipes:

—

ensure that the material used resists to temperatures up

to 120°C

For liquid pipes:

—

ensure that the material used resists to temperatures up