14

Operating Your Air Compressor

All lubricated compressor pumps dis-

charge some condensed water and oil

with the compressed air. Install appropri-

ate water/oil removal equipment and con-

trols as necessary for the intended appli-

cation.

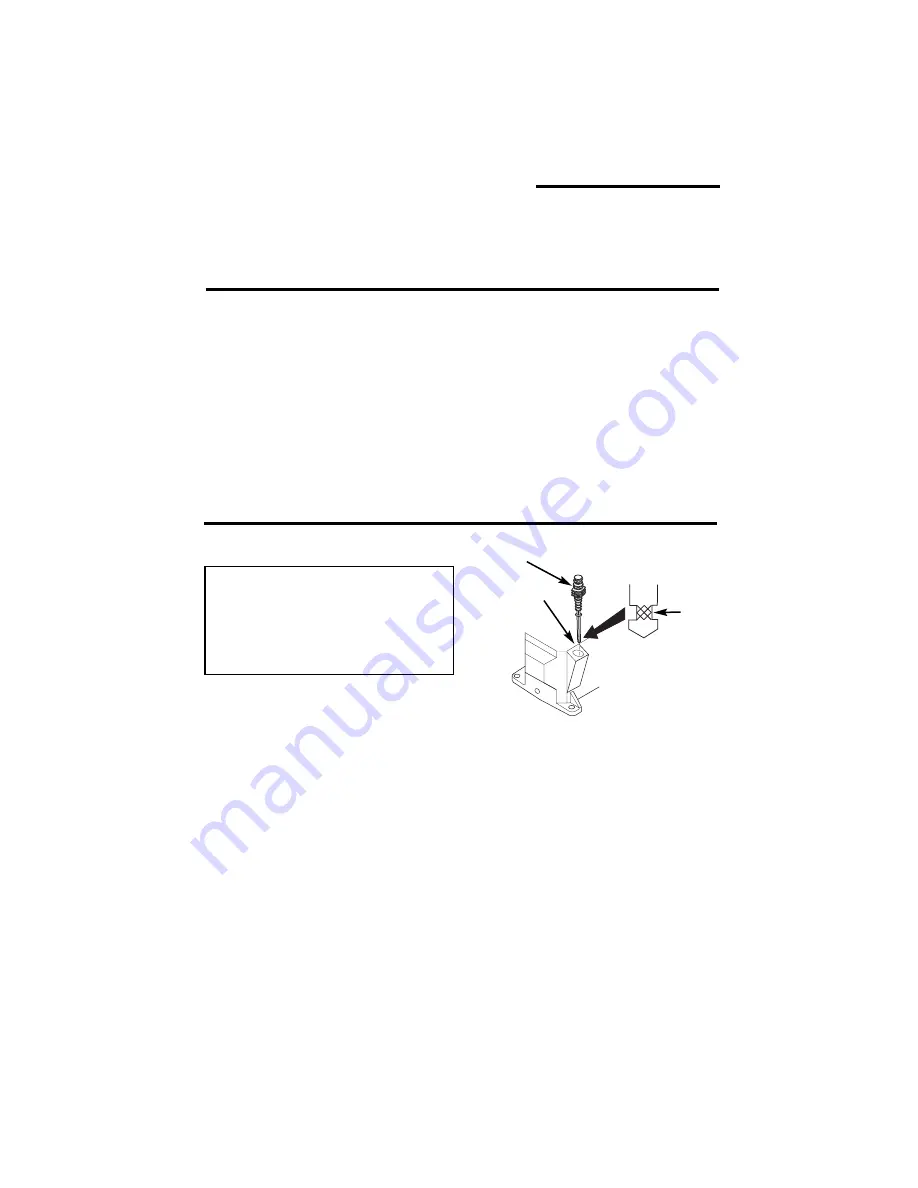

Remove the dipstick and fill pump with 12

ounces of oil. Use single viscosity, ISO

100 (SAE 30), non-detergent compressor

oil; or Mobil 1

®

5W30 or 10W30 synthetic oil

may also be used. See illustration for prop-

er oil fill.

THIS UNIT CONTAINS NO OIL!

Follow lubrication instructions

before operating compressor.

NOTICE:

Lubrication

Dipstick

Add Oil

Fill

Line

Max

Low

Moisture in compressed air will form into

droplets as it comes from an air com-

pressor pump. When humidity is high or

when a compressor is in continuous use

for an extended period of time, this mois-

ture will collect in the tank. When using a

paint spray or sandblast gun, this water

will be carried from the tank through the

hose, and out of the gun as droplets

mixed with the spray material.

IMPORTANT

: This condensation will

cause water spots in a paint job, espe-

cially when spraying other than water

based paints. If sandblasting, it will

cause the sand to cake and clog the gun,

rendering it ineffective.

A filter in the air line, located as near to

the gun as possible, will help eliminate

this moisture.

Moisture in Compressed Air