Ridge Tool Company

8

17. Pull the vent on the reservoir cap open

(Figure 6). Do

not thread with the vent closed. This will reduce

coolant flow and could cause die chipping and poor

quality threads.

Figure 6 – Reservoir Vent Open

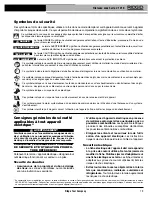

18. Move the die head down into the threading position.

Depress and hold the foot switch and look for coolant

flow between die 3 and 4 on the die head

(See Figure

7). It may take up to 10 seconds for the coolant to start

flowing if the die head has been off the machine or sat

for an extended time. Coolant should be dripping at a

rate of at least 1 drop per second. Too high a drip rate

wastes coolant, while too low a drip rate can cause die

chipping, poor quality thread and high thread temper-

atures.

19. To adjust the coolant drip rate, while depressing the

foot switch, use a flat blade screwdriver to turn the

needle pin on the die head

(see Figure 7). Clockwise

needle pin rotation decreases drip rate, while coun-

terclockwise rotation increases drip rate

Figure 7 – Adjusting Coolant Drip Rate

20. Move the die head away from the operator. Die head

position turns the coolant flow on and off while ma-

chine is running. To conserve coolant, only place die

head down in the threading position when threading or

transporting.

21. Move the ON/OFF switch to the OFF position, and

with dry hands unplug the machine.

Installing Dies and Adjusting For Size In

No. 610 Quick-Opening Die Head

The 610 quick-opening die head

(Figure 8) uses one set

of dies for

1

/

2

" and

3

/

4

" threads and another set for 1"

threads. Dies are available for NPT and BSPT thread

forms.

The 610 Die Head is designed for use ONLY with the

1210 Threading Machine. This die head is not compati-

ble with any other RIDGID threading equipment. No

other RIDGID die heads will fit on the Model 1210

Threading Machine.

1. With machine unplugged, rotate the die head retaining

knob

(Figure 7) on the carriage counterclockwise to

unlock the die head post. Remove the die head from

the carriage.

Figure 8 – No. 610 Quick-Opening Die Head

2. Lay die head on bench with numbers up.

3. Flip throwout lever to OPEN position.

4. Loosen clamp lever approximately three full turns.

5. Lift tongue of clamp lever washer up out of slot under

size bar. Slide throwout lever all the way to the end of

slot in the OVER direction on size bar (CHANGE

DIES arrow on rear of cam plate).

6. Remove dies from die head.

7. Insert new dies to indicator line on the dies.

See

Figure 9. Die numbers 1 through 4 on the dies must

1210 Oil-less Threading Machine

Needle Pin,

Drip Rate

Adjustment Screw

-

+

Look For

Coolant

Flow Here

Die Head

Retaining

Knob

Index Line

Link

Throwout

Lever

Clamp Lever

Washer

Head

Clamp Lever

Size Bar

Cam Plate