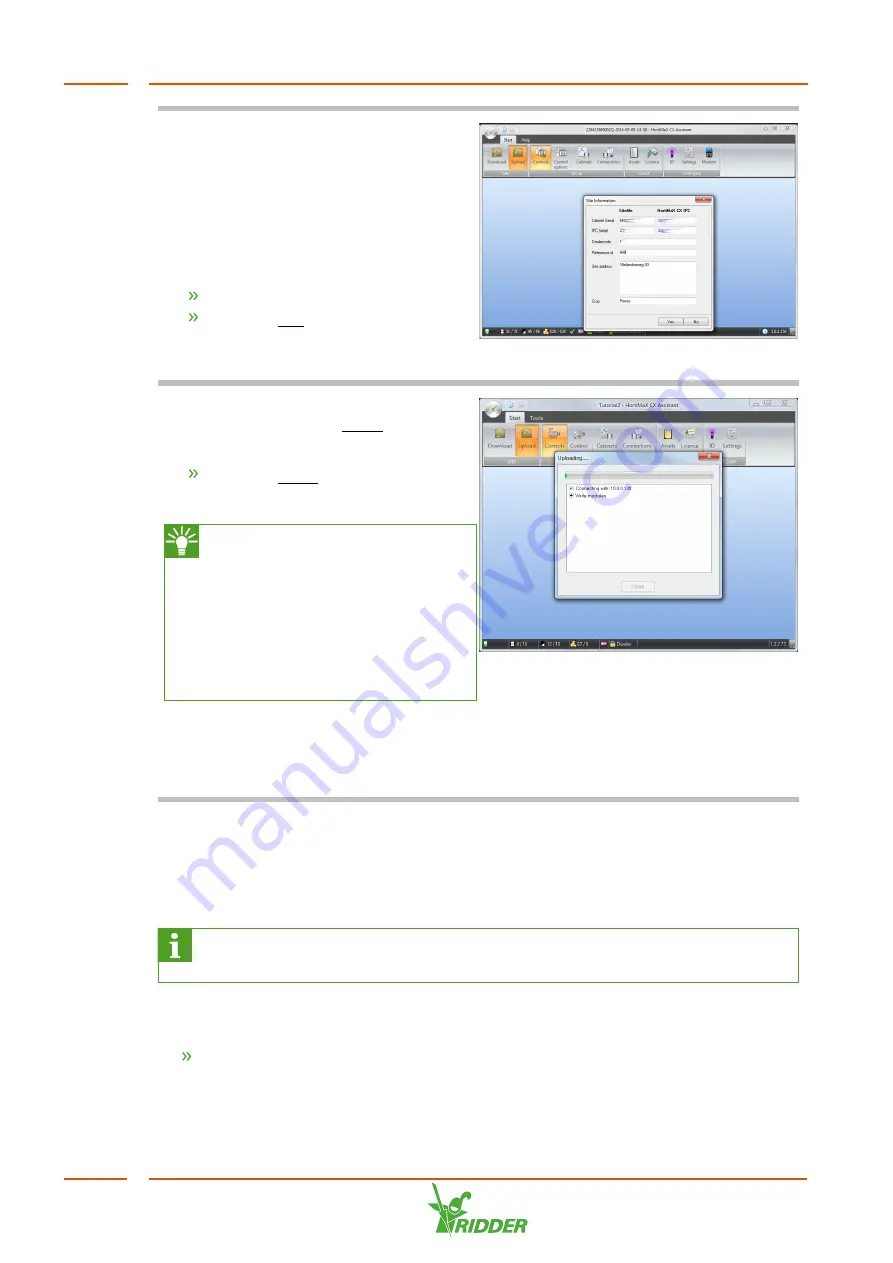

You need to complete the various fields

shown on the

Site Information

screen.

Some information, such as the reference

ID, has been provided by Ridder Growing

Solutions.

The serial numbers are pre-entered

unless you have replaced the IPC.

Complete the fields.

Click the Yes button.

The software starts uploading the site

file.

This may take some time. Once the

upload is complete, the Close button will

be enabled.

Click the Close button.

You have uploaded the site file to the IPC.

The CX Assistant allows you to

test the I/O connections. To do

this, you need to be connected to

the IPC and you must have

uploaded the site file to the

HortiMaX CX500 on the IPC. See

the "CX Assistant tutorial” guide

for more information.

If the wiring has been connected

correctly, the process computer will start

running immediately and activate the

controls based on the default settings.

5.3

Software settings

The HortiMaX CX500 can be operated using Synopta. Synopta is the operating

interface software for the HortiJet Pro and is installed on the grower’s PC / network.

For more information on Synopta, see the "Synopta software installation

guide”.

Depending on the configuration chosen for the CX Assistant, controls will become

available for use in Synopta.

Check the controls and the associated settings in Synopta.

For more information on controls and settings, please see the Synopta help. To access

this help, use the key combination [Ctrl] + [F1].

HortiJet Pro

36