Cleaning the Contact Glass

Cleaning procedure

Wipe the glass surface with the supplied cleaning cloth. Do not use alcohol to wipe the glass

surface, because it will cause uneven wiping.

1.

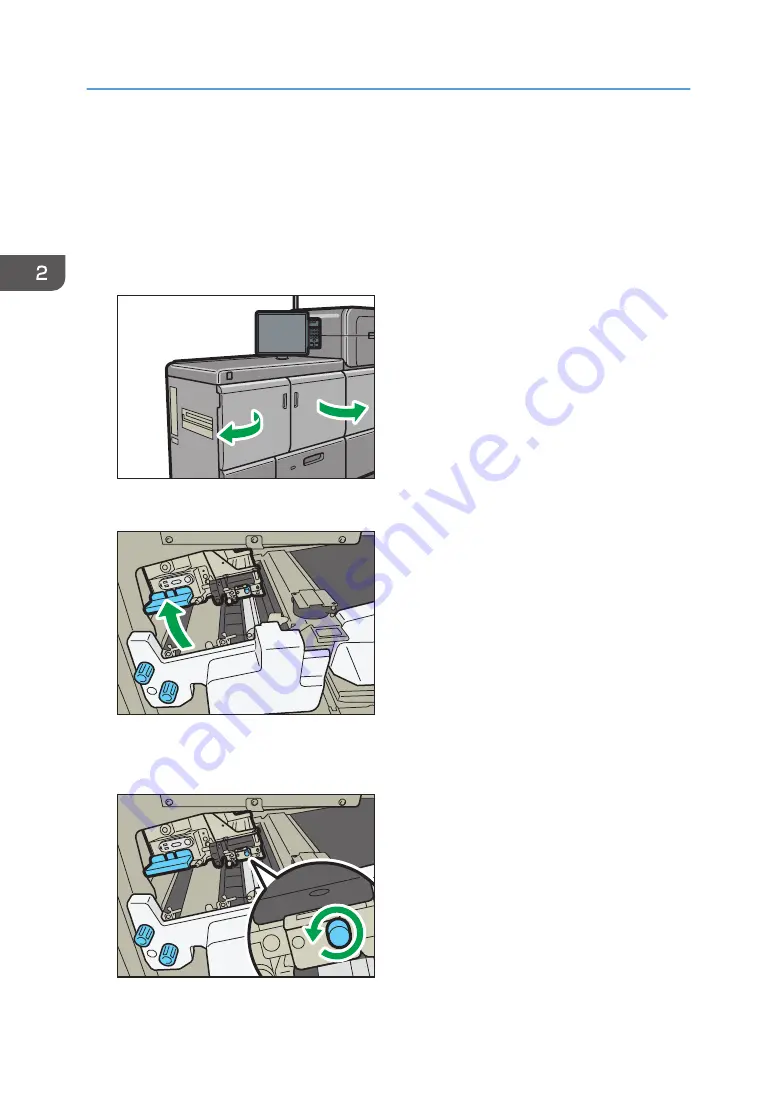

Open the left front cover of the main unit.

EAE001

2.

Raise the E3 lever.

EAE002

3.

Remove the coin screw.

If the screw does not come out easily, loosen it with a coin or similar.

M0B1IC0021

2. Troubleshooting

46

Summary of Contents for Pro C9200

Page 2: ......

Page 40: ...1 Operating and Settings 38...

Page 52: ...MEMO 50...

Page 53: ...MEMO 51...

Page 54: ...MEMO 52 EN GB EN US EN AU M0B2 1334C...

Page 55: ...2019 2020 2021...

Page 56: ...M0B2 1334C AU EN US EN GB EN...