8

ATV Portable Truck Scale Assembly Instructions

Be certain each load cell grounding strap is securely

connected to the top plate and bottom plate of each

load cell mount. Some models have ground straps

i n c l u d e d t o i n s t a l l b e t w e e n m o d u l e s . T h e s e

inter-module straps ensure that the entire scale is

connected to the same single-point ground. There

should be metal-to-metal contact with no presence of

paint or grout. This strap is designed to channel power

surges on the deck around—rather than through—the

load cell to ground. A thick coating of anti-oxidant

g r e a s e s h o u l d b e m a i n t a i n e d o n a l l g r o u n d

connections to prevent corrosion.

A separate grounding system conductor must extend

uninterrupted from the main service panel ground to

the scale to protect load cells and scale wiring from

lightning and other transient damage. This ground

wire conductor must be an unsheathed #10 copper

wire or larger. Run the bare ground wire conductor

intact from the AC power ground rod to the scale in a

separate trench.

Bring the wire up from the trench

near the J-box and attach it to the ground lug located

in the J-box pocket. This grounds the scale frame to

the same single-point ground as the AC power for the

indicator.

A ground wire is included to attach the J-box ground

lug to the ground lug located in the J-box pocket.

Grounding of the J-box is essential for operation of

the DC transient protection incorporated into the

J-box.

3.5

Installing Transient Protection

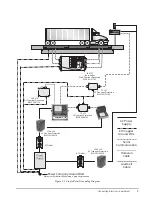

A two-year lightning protection package comes standard all truck scales. The individual components of this

comprehensive package are designed to protect AC and DC portions of the system. The lightning protection

package includes:

•

DC transient protection included with standard J-box board(s). This DC transient protection handles up

to eight load cells. Scales with more than eight load cells require additional J-boxes.

•

Self-contained DC transient protection unit in the homerun cable at the indicator.

•

A 115 VAC uninterruptable power supply/surge protector in the AC line before the indicator.

•

Number 10 bare ground conductor cable buried in earth from scale frame to DC transient board at

indicator and finally to the AC power ground lug.

Figure 3-2. Grounding and Transient Protection on ATV Scale

NOTE

: Serial communications (if used) may also require transient protection to fully protect entire system. A TP-232 DC Transient

Protection is suitable protection for serial communications lines. In addition, printers, remote displays and other devices

connected to serial communications should be protected with AC transient protection.

10 ga. bare ground wire to DC

protection ground before indicator

Ground Lug

Located in

J-box Pocket

Summary of Contents for SURVIVOR ATV series

Page 1: ...ATV Portable Truck Scale Assembly Instructions 68982...

Page 2: ......

Page 4: ...ii ATV Portable Truck Scale Assembly Instructions...

Page 20: ...16 Assembly and Foundation Drawings Figure 7 2 ATV Single Module 30 Assembly Drawing...

Page 21: ...ATV Portable Truck Scale Assembly Instructions 17 Figure 7 3 70 x 11 ATV Pier Foundation Print...

Page 22: ...18 Assembly and Foundation Drawings Figure 7 4 30 ATV Pier Foundation Print...