TM012 Rheem Electric Water Heaters Service Instructions REV: B

Date of Issue: 03/06

This document is stored and maintained electronically by

Service. All printed copies not bearing this statement in RED are deemed “uncontrolled”

31

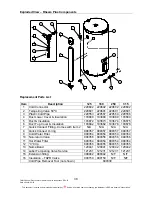

Element – Top and Bottom (Procedure 10)

Elevated temperatures may be present during element removal process.

Personal Protective Equipment should be worn to prevent the risk of

scalding.

Personal Protective Equipment should be worn when conducting step 2

of this procedure to reduce the risk of electric shock. Refer to Rheem

Safety Procedure on electrical testing.

When replacing an element on a heater with a cylinder barrel that does

not have an earth tab (refer to page 8) ensure that the metal surround of

the element flange is in direct contact with the cylinder barrel flange thus

ensuring a good Earthing contact and conduct an earth continuity test as

required by AS/NZS 3000 6.3.3.2.

When a fault or leak is traced to the element, the water heater should be drained to

prevent damage to flooring or floor coverings by accidental flooding.

1.

Isolate power and water supplies

and remove the lower access cover

.

2.

Confirm with a multi-meter between each Active and Neutral at the terminal block

that voltage is not present.

3.

Relieve pressure from water heater through the T & PR valve or a hot tap.

4. Drain the water heater. Refer to procedure 1 on page 26.

5. When the water heater is drained, undo the four element screws, removing thermostat

clamp first.

6. Withdraw heating unit. Care must be taken to ensure the loop of the heating unit does

not catch in the cylinder opening and open out inside the cylinder.

NOTE: Do not “cut off” the heating unit and leave a portion inside the cylinder

7. Clean around cylinder fitting, fit gasket to new element and slide heating unit into

cylinder (reverse to step 6) taking care that it is in the correct orientation. See heating

unit plate for directions.

8. Replace screws and thermostat clamp and tighten.

9.

Models manufactured after 7/11/05 without an element flange Earth

tab

.

The earthing of the internal storage cylinder relies on a good

electrical contact between the metal surround of the element flange

and the cylinder barrel flange.

An earth continuity test should be performed whenever an element

or element gasket is replaced, adjusted or serviced in any way. This

continuity test is performed between the heaters internal storage

cylinder and the main earth terminal of the water heater with a

resulting reading of not more than 0.5 ohms as required by AS/NZ

3000 6.3.3.2.

10. Restore cold water supply and fill the storage tank by gently lifting the easing lever on

the T & PR valve until water runs from the drain.

11. Check for water leaks around the element flange.

12. Conduct an electrical insulation test. (Refer to page 25)

13. Replace access cover securely and restore electrical supply.