TM012 Rheem Electric Water Heaters Service Instructions REV: B

Date of Issue: 03/06

This document is stored and maintained electronically by

Service. All printed copies not bearing this statement in RED are deemed “uncontrolled”

27

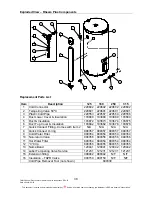

Dip Tube (Procedure 3)

1.

Isolate the power and water supplies to the water heater.

2.

Relieve pressure from the water heater through the T & PR valve or a hot tap.

3. Disconnect the hot water line from the outlet of the water heater.

A quantity of hot water will discharge from the outlet during this process.

Personal Protective Equipment should be worn to prevent scalds or burns.

4. Remove the extension fitting (80L– 400L models).

5. Using a flat blade screwdriver gently split the outer rim at the top and bottom of the dip

tube face and prise the dip tube out of the cylinder fitting.

6. Fit the replacement dip tube into the cylinder fitting ensuring the flat lines up with the

fitting (dip tube facing up) and gently drive the dip tube into the fitting a short distance.

7. Apply thread tape to the extension fitting and refit; this will push the dip tube into the

correct location.

8. Reconnect the plumbing and restore the water supply.

9. Purge air from the system through hot taps.

10. Restore the power supply.

Anode (Procedure 4)

Elevated temperatures may be present during anode removal process.

Personal Protective Equipment should be worn to prevent the risk of

scalding.

1.

Isolate the power supply to the water heater.

2.

Isolate water supply to the water heater.

3.

Relieve pressure from the water heater through the T & PR valve or a hot tap.

4. Remove the anode cap.

5. Using a 27mm tube or socket spanner remove the anode.

6. Apply thread seal tape to replacement anode, refit and tighten.

Note:

It may be

necessary to cut the anode to length prior to fitting. Refer to page 4 for the correct

anode length.

7. Restore water supply and check for leaks.

8. Refit the anode cap.

9. Purge air from the system through hot taps and restore the power supply to the water

heater.