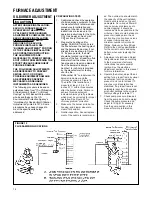

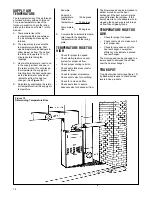

BURNER

For proper operation, replace the

burner oil nozzle each year. It is

located in the burner drawer. (See

instructions furnished with burner for

details.)

Periodically clean ignition electrodes,

blower wheel and all filters in the oil

line. Service should be performed by a

qualified service technician at least

once yearly at the beginning of the

heating season.

18

LUBRICATION

IMPORTANT: DO NOT

attempt to

lubricate the bearings on the blower

motor. Addition of lubricants can

reduce the motor life and void the

warranty.

The blower motor is permanently

lubricated by the manufacturer and

does not require further attention.

The blower motor must be cleaned

periodically by a qualified installer,

service agency, or the oil supplier to

prevent the possibility of overheating

due to an accumulation of dust and dirt

on the windings or on the motor

exterior.

AIR FILTER

The air filters must be kept clean. Dirty

filters can restrict airflow. The motor

depends upon sufficient air flowing

across and through it to keep from

overheating.

In a new house, the air filter may

become clogged within a short time

due to the presence of dust in the air

and air ducts. A dirty filter retards the

flow of air and prevents proper airflow.

Permanent filters should be cleaned

and disposable filters should be

replaced at least once a year and more

often if necessary (see User’s Info.

Manual).

NOTE:

Do not use high static return

air filters to replace standard furnace

filters.

MAINTENANCE

Summary of Contents for LX2000 Series

Page 27: ...27 PARALLEL WIRING UPFLOW OIL FURNACES SCHEMATIC...

Page 28: ...28 HEATING AND COOLING CONTINUOUS LOW SPEED BLOWER SCHEMATICFIGURE 38...

Page 29: ...29 FIGURE 38 FOR MODELS WITH UTEC 1012 925 INTEGRATED FURNACE CONTROL...

Page 30: ...30...

Page 31: ...31...

Page 32: ...32 CM 898...