12

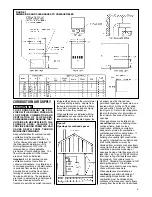

FIGURE 12

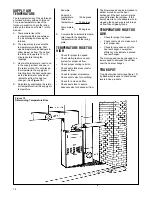

FLUE SAMPLING LOCATIONS

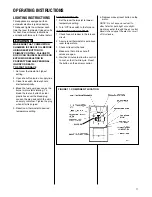

OIL BURNER ADJUSTMENT

AFTER FURNACE INSTALLATION,

EACH OIL FURNACE MUST BE

OPERATED IN THE HEATING

CYCLE AND PROPER BURNER

ADJUSTMENTS COMPLETED FOR

EACH FURNACE INSTALLATION

FIELD CONDITION. THIS IS

REQUIRED FOR EACH OIL

FURNACE INSTALLED. SEE

“BURNER ADJUSTMENT” PORTION

OF THE FURNACE INSTALLATION

AND OPERATINIG INSTRUCTION.

THE ADJUSTMENTS ARE

NECESSARY TO PREVENT SMOKE,

SOOT, ODOR FROM ENTERING THE

STRUCTURE AND SUBSEQUENT

FURNACE DAMAGE.

THE FOLLOWING ADJUSTMENTS

ARE NECESSARY TO PREVENT

SMOKE, SOOT, ODOR AND

POSSIBLE EQUIPMENT DAMAGE.

AN EXPERIENCED SERVICE

MECHANIC AND RELIABLE

INSTRUMENTS ARE REQUIRED.

The following procedure is based on

guidelines taken from

"The Profession-

al Serviceman's Guide To Oil Heat

Savings" by R.W.Beckett Corporation,

who based theirs on the U.S.

Environmental Protection Agency's

"Guidelines for Residential Oil Burner

Adjustments" printed in 1975. Some

procedures have been changed to

meet the specific units being

addressed.

CAUTION

!

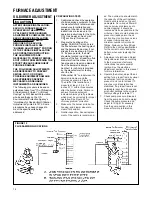

FURNACE ADJUSTMENT

PREPARATION STEPS

1.

Calibrate and check the operation

of all measuring equipment. Follow

the manufacturer's recommended

procedures for calibration and

equipment check out. Calibration

instructions are included in the

operation instructions for the Fyrite

CO2 Gas Analyzer. See Fyrite

CO2 section in this manual.

2.

Prepare the heating unit for

testing. Drill ONE 1/4 inch hole in

the flue between the heating plant

and the barometric damper, if not

already there as shown in Figure

12. If space permits, the hole

should be located in a straight

section of the flue, at least two flue

diameters from the elbow in the

flue pipe and at least one diameter

from the barometric damper.

Another 1/4 inch hole is provided

by the manufacturer for testing

over the fire.

Drill another 1/4

(

hole between the

barometric damper and the

chimney as shown in Figure 12.

The draft at this location must

measure at least -.05 to -.06

inches W.C. within three minutes

after the burner starts. Failure to

achieve this measurement

indicates chimney draft problems

which must be corrected for proper

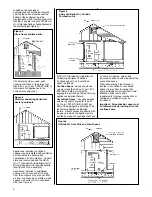

operation. See Figure 22 for

chimney problem correction.

3.

Make sure the burner air tube, fan

housing, and blower wheel are

clear of dirt and lint.

4.

Nozzle inspection. Annual replace-

ment of the nozzle is recommend-

ed. The nozzle size should match

the capacity of the unit installed.

Nozzle si/ze is listed on the unit

nameplate. An in-line oil filter will

reduce service problems due to

nozzle clogging. It should be

located as close as possible to the

oil burner. Care should be taken to

prevent air leakage into the oil

suction line. Use continuous runs

of copper tubing and use a

minimum number of joints and

fittings. Always use flare fittings.

Refer to the nozzle specifications

for the correct nozzle and spray

pattern, whenever replacing the

nozzle.

5.

Adjustment of electrodes. Adjust

the ignition electrodes according

to the burner manufacturer’s

instructions to assure prompt

ignition. See the electrode

adjustment section in this manual

for more information.

6.

Operate the burner; adjust the air

setting for a proper flame by visual

observation (until no smoke is

present), and run for at least 10

minutes or until operation has

stabilized. If a proper flame is not

obtainable reset the air band and

air shutter settings to the original

factory settings (see table 11).

7.

Check pump pressure. Bleed air

from the pump and nozzle piping.

Check the pump pressure and

adjust to 100 psi, if necessary.

See the pump section in this

manual for more information.

Summary of Contents for LX2000 Series

Page 27: ...27 PARALLEL WIRING UPFLOW OIL FURNACES SCHEMATIC...

Page 28: ...28 HEATING AND COOLING CONTINUOUS LOW SPEED BLOWER SCHEMATICFIGURE 38...

Page 29: ...29 FIGURE 38 FOR MODELS WITH UTEC 1012 925 INTEGRATED FURNACE CONTROL...

Page 30: ...30...

Page 31: ...31...

Page 32: ...32 CM 898...