2

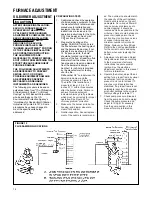

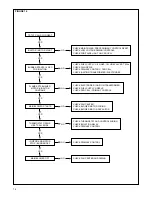

Before beginning any troubleshooting procedure, complete the following installation checklist. A furnace malfunction is

sometimes caused by an improper installation. By completing this checklist, the problem may be found and corrected. Make

copies of the checklist and complete one for every Low Profile Furnace service call for your records.

INSTALLATION CHECKLIST

(Refer to this manual for specifics.)

GAS SUPPLY

Adequate pipe size

No gas leaks

Proper supply and manifold gas pressure (check with an accurate U-tube manometer with the furnace and all other gas

appliances operating.)

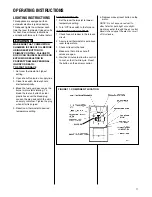

ELECTRICAL

Correct thermostat and subbase

Thermostat model

Subbase model

Correct thermostat mode and setting

Correct line supply voltage

Correct polarity (important with hot surface ignition)

Correct furnace ground to electrical panel

DC microamp (

µ

A) flame signal (hot surface ignition units)

Correct control voltage

Measure and set heat anticipator amperage

Air conditioning low voltage wires connected to terminals “Y” “C” - not with wire nuts

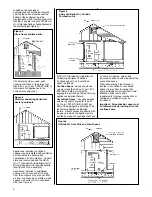

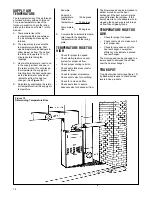

VENTING

Correct vent pipe diameter and length (according to AGA/GAMA tables)

Vent connection size

Correct venting material (according to AGA/GAMA tables)

Correct lining for masonry chimneys

Adequate clearance from combustibles

Proper negative pressure reading in the vent

Vent pipe secured to induced draft blower housing

COMBUSTION AIR

Proper source of combustion air

Correct combustion air opening size

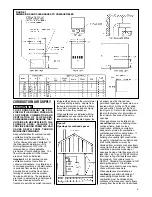

FURNACE INSTALLATION

Adequate clearance from combustibles

Adequate clearance for service

Proper air temperature rise (See furnace rating plate)

External static pressure

inches w.c.

Correct filter(s)

Correct cooling coil or accessories (if equipped)

Adequate supply and return air ducting

Return Air Duct Size

Supply Air Duct Size

Air ducts sealed to prevent leakage

Summary of Contents for LX2000 Series

Page 27: ...27 PARALLEL WIRING UPFLOW OIL FURNACES SCHEMATIC...

Page 28: ...28 HEATING AND COOLING CONTINUOUS LOW SPEED BLOWER SCHEMATICFIGURE 38...

Page 29: ...29 FIGURE 38 FOR MODELS WITH UTEC 1012 925 INTEGRATED FURNACE CONTROL...

Page 30: ...30...

Page 31: ...31...

Page 32: ...32 CM 898...