Appendix D

•

Falk

™

Drive One

®

Enclosed Gear Drives

(Page 20 of 27)

Type D Series

•

Sizes M1130 thru M1210

168-050

Rexnord Industries, LLC, 3001 W. Canal St., Milwaukee, WI 53208-4200

January 2019

Telephone: 414-342-3131 Fax: 414-937-4359

Supersedes 04-11

e-mail: [email protected] web: www.rexnord.com

(PN 2124650)

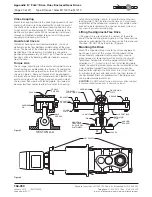

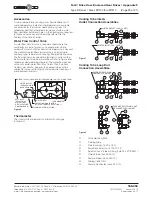

Close Coupling

Mount the coupling hubs to the drive high-speed shaft and

motor shaft. Hubs are to be mounted flush with the end of

the shafts unless otherwise noted (coupling hubs may be

furnished with an interference fit). Mount the motor to the

bell housing, apply Loctite #242 or equivalent to fastener

threads and tighten to proper torque. Install high-speed

coupling per coupling instructions.

Guards and Covers

Install bell housing covers (top and bottom). Install air

deflectors on the top, bottom and both sides of the gear

drive. The bends of the deflectors are perforated to allow

positioning of the deflectors. Air deflectors should be

positioned approximately 25 mm (1 inch) from the nearest

housing surface by bending deflector towards or away

from the drive.

Torque Arm

The carriage, adjusting rod, brackets and support bar are

furnished pre-assembled from the Factory. Assemble the

rod ends with heads perpendicular to each other (90°) as

shown in Figure 3. Rod end threads must be engaged a

minimum of one times thread diameter. Attach female rod

end to carriage with pin. Place a spacer on each side of

the rod end. Secure pin with locking plate. Carriage may

be adjusted from center to either far end of the housing

to facilitate installation of pin. Ensure that adjusting rod

locking plate is NOT installed at this time as it will prevent

adjustment of the torque arm assembly. Assemble anchor

bracket to male rod end with a spacer on each side and

secure with pin and retaining ring.

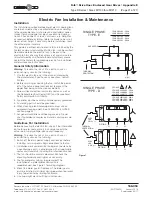

Lifting the Alignment-Free Drive

Lifting points are provided on the corners of the motor

end of the bell housing. See Figure 4. Lift by these and the

provisions provided on the drive housing itself to maneuver

the drive. DO NOT lift by the motor lifting eye.

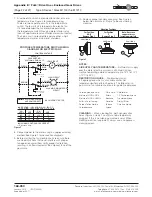

Mounting the Drive

Mount the Alignment-Free drive to the driven equipment

per Pages 2 and 3 of this manual. With Alignment-Free

drive assembly supported, rotate adjusting screw to

move torque arm to desired position and to line up with

foundation. Torque Arm must be perpendicular in both

directions (± 1°). Adjust screw if not. Install locking plate

to lock the adjusting screw (plate can be installed on either

side). Remove support from drive and secure anchor

bracket to foundation. Use M24 Class 8.8 (1 inch Grade

5) or better fasteners with lock and flat washers to mount

anchor bracket. Slots are provided such that torque arm

can be mounted perpendicular.

CAUTION

: Do NOT adjust torque arm screw after support

is removed and torque arm is under any load.

A

CARRIAGE

PIN

SPACER

FEMALE

ROD END

MALE

ROD END

SECTON A-A

THREADED

ADJUSTING ROD

BRACKET

ADJUSTING

SCREW

LOCKING

PLATE

CARRIAGE

PIN LOCKING

PLATE

BRACKET

SUPPORT BAR

RETAINING

RING

ANCHOR

BRACKET

SPACER

MOUNTING

HARDWARE

(SUPPLIED BY

CUSTOMER)

PIN

JAM NUT

A

Figure 3

LIFT POINTS

Figure 4