All installations and services must be performed by qualified service personnel.

17

MAXIMUM VENT LENGTH

VENT SIZE

2 IN. PVC

FURNACE

MODEL

VENT

LENGTH

(FT.)

EXHAUST

VENT

ELBOWS

(NO.)

COMBUSTION AIR INTAKE

ELBOWS (NO.)

VMA

30

8*

7**

*Note the drain elbow supplied with VMA furnaces count as 1 elbow.

**Note the two 45

°

elbows supplied w/VMA furnace count as 1 elbow.

Table 2

6. A hack saw may be used to cut the PVC pipe. It must be cut smoothly at

right angles with all burrs removed. All joints must use standard PVC

Schedule 40 elbows and couplings. Joints are not to be made by gluing,

except where noted, and butting together the cut or raw edges of the vent

pipe. (The joints inside the vestibule should be sealed with a silicone caulk to

allow for maintenance.)

Notice:

Do not use silicone caulk to seal the PVC

sleeve or coupling to the metal air intake collar on the burner box. The

screw securing the sleeve or coupling to the collar is sufficient.

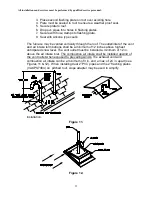

7. Use the two radiator hose clamps to connect both the exhaust vent and

combustion air vent pipes to the venting system (included in the parts

package.) This will aid in the serviceability of the vent should it need to be

removed in the future. (Refer to figure 6).

8. Vent connections shall be checked for leakage with the furnace induced

draft blower running and with the vent termination blocked. A mild soap and

water solution may be used to check for leaks.

9. Vent pipe passing through an unheated space must be insulated with 1.0”

thick foil faced fiberglass insulation or its equivalent to prevent freezing of any

condensate within the pipe.

10. Minimum clearance from the PVC pipe to combustible material is zero

inches.

IMPORTANT:

The VMA furnace models are vented through the roof. For

roof venting refer to Section IV, J, of this manual.