All installations and services must be performed by qualified service personnel.

24

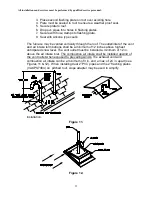

inlet as shown in Figure 10, making sure that the spacing between the inlet and

outlet complies with that noted in Figure 8.

Figure 10: Typical Construction Details of Sidewall Vent and Air Intake

Terminations

3. Finish the vent installation by caulking the annulus to seal around the two (2)

holes where the thermoplastic pipes pass through the wall.

4. To prevent foreign material, insects, or small animals from entering the pipes,

an optional vent or intake terminal (stainless steel) screen is available from the

furnace manufacturer, part no. V320219.

J. CONNECTING THE FURNACE TO ROOF VENT / AIR TERMINATIONS

The VMA is designed to be vented with either a concentric vent assembly or twin

2” pvc stacks. The concentric vent (VAOPS7515) can be vented through the

ceiling/roof either thru the existing roof jack or thru the 3” ceiling/roof flashing

plate.

Concentric vent utilizing existing roof jack as a chase.

Follow instructions included with concentric vent kit VAOPS7515.

Concentric vent without roof jack as a chase.

Follow instructions included with concentric vent kit VAOPS7515.

Dual 2” vent/air termination kit VAOPS7484

1. Remove roof jack assembly.

2. Place a 2” (2-holes) ceiling/roof flashing plate to the ceiling centering it

over existing hole.