All installations and services must be performed by qualified service personnel.

13

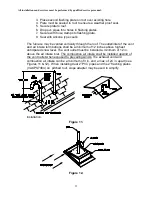

connector duct. Remove the bottom panel. Cut an opening in the distribution duct

slightly larger than the connector duct. (refer to Figure 2 for location of this cut.)

Cut the connector duct to length. Install the connector duct. Bend over each tab.

Insure an airtight seal by using high temperature sealant or tape on the joint.

Reinstall the bottom panel over the connector duct. Put the base top assembly in

place (see Figure-3).

Slit the corners of connector duct down to the top of the base assembly. If metal

projects more than 1-inch above the top of the base assembly, trim the flanges

down to 1-inch. While the top of distribution duct is being pulled up with one

hand, bend down each side of the connector duct tightly to the base assembly

with the other hand. This assures a tight connection between the base assembly

and the connector duct and that the distribution duct will be full size. Use high

temperature tape and/or high temperature silicone caulking on all joints and

seams to minimize air leakage. Secure the base assembly to the floor with two

screws in the front flange.

2. Cottage Base Model: VCOT-BASE

The VCOT-BASE cottage base (Figure 1C) is required for a freestanding cottage

base installation. The cottage base allows the two sides and rear to have an 8” x

12” register installed.

IMPORTANT: All joints and seams of supply ducts

must be sealed with a sealing method suitable to the application conditions

and temperatures (I.E. High temperature silicone and/or aluminum tape).

Refer to assembly and installation instructions included with cottage base for

additional information.

C. ALCOVE INSTALLATION

In this application, a minimum of 18 inches of clearance

must

be provided to the front of the unit. See Figure 4.

Note – access to diagnostic view port.

Figure 4.