8

The crank handle offers tremendous leverage; so do not use too much force. Allow the cutting tool to

determine the pace. With experience, the operator will be able to determine the best pace to feed to

the work. There should be some degree of audible slowing of the motor but not bogging in the cut.

Correct cutting speed with a properly sharp annular cutter will produce long unbroken chips, which

produce a “bird’s” nest. shaped bundle of chips around the cut.

NOTE: Always ensure that the cutting tool is sharp. A dull cutter typically will have finer and/or choppy

shavings.

WARNING: ALWAYS clear chips when there is too much build-up. Excessive chip build-up could result in a

jammed cutter or other hazardous situation.

WARNING: The slug ejects at end of cut and is very hot. Always provide a method of catching the slug,

where the ejected slug may cause injury to people below.

CAUTION: Never attempt to cut half-circles or to stitch drill (drill overlapping holes) with a TCT cutter. This

may destroy the cutter.

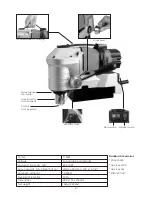

REVERSING OR CHANGING THE POSITION OF THE CRANK LEVER

The Crank Lever is quick-release and adjustable to suit different operating conditions.

If it is required to mount the crank lever on the opposite side or to change its position, push the Release

Button in the center of the Crank Hub and remove. Press the Button and mount on the opposite side or in

the desired position.

Crank Lever

Release Button

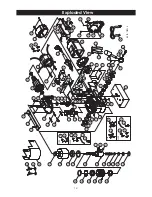

Summary of Contents for Low Profile 35

Page 11: ...11 Wiring ...