07

Installation Considerations

Modules must be mounted using the mounting holes located on the rear side of the long frame

parts using M6 or M8 bolt stainless steel bolts, nuts, and washers. Refer to the racking

manufacturer for specific torque requirements.

The mounting design must be certified by a registered professional engineer and comply with

local code requirements from relevant authorities.

Fastening

All installation methods herein are only for reference and Renogy will not provide their own

mounting components. Instead, the system installer is responsible for making sure

installation is abided by all codes.

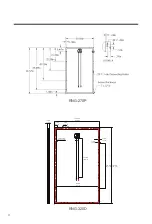

Module mounting must use the pre-drilled mounting holes (Length * Width: 14mm x 9mm)

in the frame. The most common mounting is achieved by mounting the module using the

four symmetry points close to the inner side of the module frame. Refer to the following

picture for more details. Note that the holes in the center (blue) are for grounding.

RNG100D Example