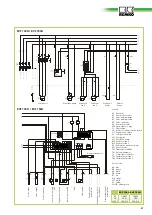

The systems are equipped

with a phase sequence relay

which prevents the operation

of the controller if the phrase

sequence for the electric mains

connection is wrong.

The phrase sequence must be

corrected if the controller is

not activated during

commissioning.

NOTE

During manual bleeding, es-

caped glycol mixtures must be

disposed of separately.

NOTE

Additional checks

General checks

■

Checking that minimum clear-

ances are correct.

■

Check the outlet possibility of

the cooling and heating, for

the cold and hot water outlet

(indoor unit).

Electrical checks

■

Checking electrical connections

for correct phase sequencing.

■

Check that the operating

contact cooling mode/heating

mode works (option).

■

Check that the enabling contact

on / stand-by works (option).

Checking the medium cycle

■

Check the circulating pump for

free flow.

■

Check that all valves are open.

■

Check the medium cycle.

■

Set the circulation pump’s flow

volume.

Checking the cooling cycle

■

Checking the cooling cycle for

adequate oil/coolant.

■

Check the cooling cycle for

leaks.

Expansion vessel

■

The preliminary pressure for the

diaphragm expansion vessel must be

adjusted individually to the system

layout, the volume of the medium

and the installed position.

■

If necessary, change the installed.

For this, the manufacturer’s au-

thorisation is required.

■

For the cooling and heating

systems, the volume and the

preliminary pressure for the

diaphragm expansion vessel must

be adjusted to both operating

modes; integrate an additional

diaphragm expansion vessel in

the system if necessary.

Valve for hydronic balancing

■

The pressure in the pipe system

of the individual cold water

outlets can be adjusted at the

valves.

Safety valve

■

The safety valves must be

checked that they are working

correctly.

■

The drain line for the valves

are to be checked that they are

clear and leak tight.

■

If necessary, change the in-

stalled position.

For this, the manufacturer’s

authorisation is required.

33

Summary of Contents for RVS 100H INOX

Page 2: ......