5

Set Up

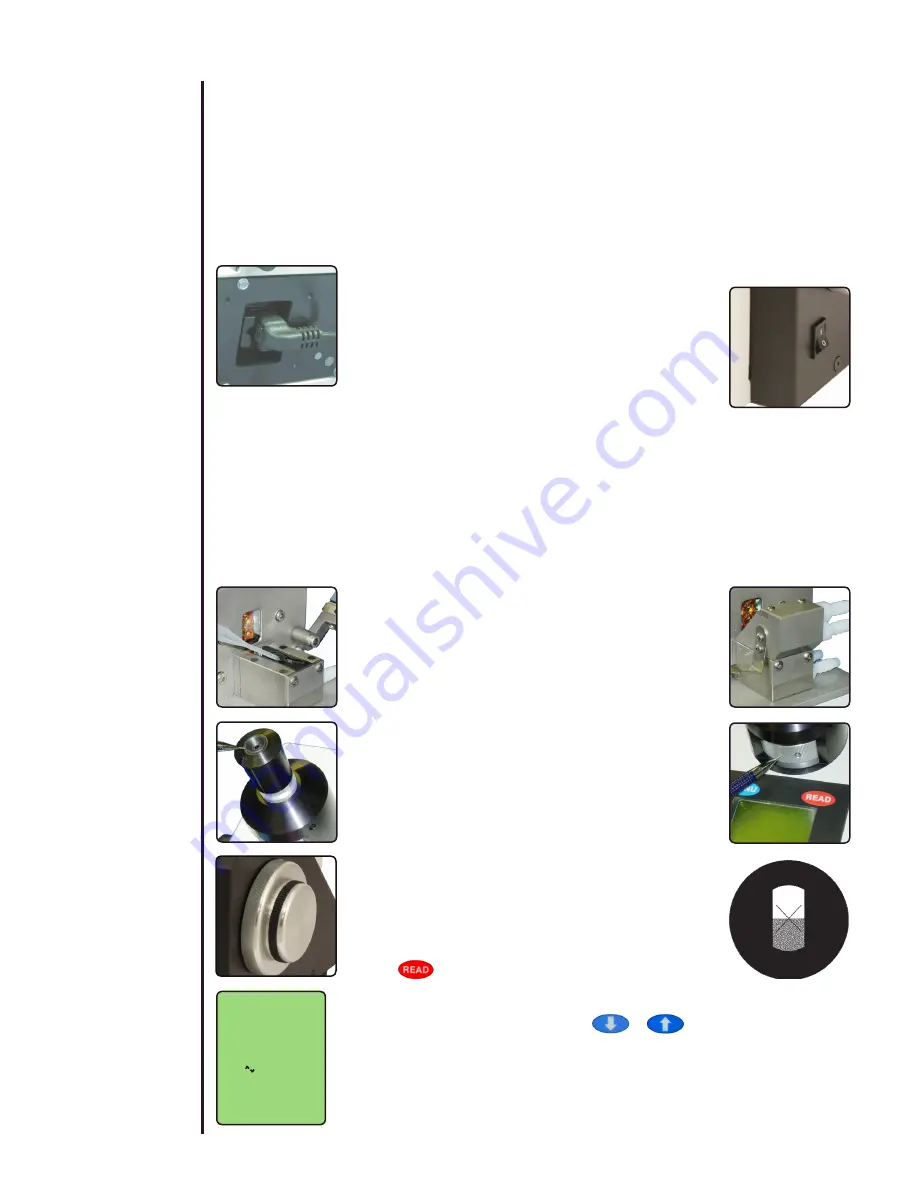

- Unpack the instrument from shipping carton. Retain packing material for future storage/

protection/shipping.

- Place the instrument indoors on a solid surface in an environment where the temperature

is stable. Be certain that the instrument is not subjected to direct discharge from heating or

air conditioning vents, or water bath circulator exhaust. Drafts can have an adverse affect on

temperature stability.

- Insert the appropriate plug end into the power receptacle located on the underside of the

instrument. Plug the opposite end of the power cord into a receptacle to supply the instrument

with power (Fig 1). Supply voltage: 100 - 240VAC

50/60HZ.

- Turn the instrument on by activating the power switch

located on the right side cover (Fig 2).

- Allow the instrument to reach a stable operating

temperature in the on position for a minimum of

one hour before attempting calibration or to measure

samples.

Fig 1

Fig 2

Sample Analysis

Cleanliness, sample temperature equilibration and shadowline clarity is essential to obtain the

greatest possible accuracy from the Mark III refractometer. Highly viscous samples or samples

that contain trapped air bubbles may not produce a sharp shadowline. In these cases, applying

the sample with a rubber spatula to squeeze out trapped bubbles or lifting the upper prism sev-

eral times to remove the trapped air is required. The following are the required steps to properly

analyze a sample:

Raise

the upper prism and apply the sample to a

clean measuring surface (Fig 3).

Gently

lower the upper prism to spread the sample

evenly and to eliminate trapped air bubbles (Fig 4).

Allow

the sample to reach temperature equilibration

with the instrument.

View

the image through the focusing eyepiece (Fig 5).

If required, rotate the eyepiece to bring the image of the

“X” pattern into focus.

If

a non-distinct shadowline containing color is viewed,

rotate the color dispersion correction wheel to eliminate

or reduce the color dispersion (Fig 6). Under optimal

conditions, the shadowline area will appear to be sharp

and black with a bright area above.

While

viewing the image, center the shadowline in the

“X” pattern by rotating the shadowline adjustment knob

(Fig 7). For measuring consistency, always approach

the center of the “X” pattern with the shadowline from

below. Once the image has been centered (Fig 8)

press .

To

the left is a representation of a displayed value. To

change reading mode, press either or to

advance through all available mode options.

1.3330

20.00

o

C

Sucrose

I I Index-TC

Time

Date

Temp

o

C

Fig 5

Fig 3

Fig 4

Fig 7

Fig 8

Fig 6