│

18

6 - Installation and Commissioning

Installation shall meet valid rules and may be done by quali

fi

ed staff only.

Defects caused by improper installation, use or handling are not covered by warranty.

After the tank is installed and connected to an existing heating system, it is recommended to clean

the entire heating system using a suitable cleaning agent, e.g. MR-501/R.

Anti-corrosion protective liquid should be also used, e.g. MR-501/F.

6.1 - Connecting heat sources

The tank shall be placed on the

fl

oor, as close to the heat source as possible. Mount the insulation,

see Chapter Mounting insulation onto the tank. Connect heating circuits to the inlets and outlets re-

specting the temperature distribution in the tank. Insulate all the connecting piping.

6.2 - Connecting a solar thermal system

This tank can be also connected to a solar thermal system. An extra

fl

ange and a tube heat ex-

changer (coil) will be needed, depending on the output of the solar thermal system. All connecting

pipes between the tank and solar collectors shall be insulated meticulously.

6.3 - Installing a heating element

The Thermal Store can be

fi

tted with two 3-phase electric heating elements with a longer non-heat-

ing end (ETT-C or ETT-L), 6 kW max. output each, or with two single-phase electric heating ele-

ments with a longer non-heating end (ETT-M), 3 kW max. output each. They can be wired directly to

the mains (heating elements equipped with own thermostat), or via a Controller for the entire heating

system.

All el. heating elements shall be installed together with a safety temperature limiter.

An el. heating element shall be wired by quali

fi

ed staff only.

6.4 - Connecting sanitary water piping

DHW piping shall be done according to valid rules. Installation of a pressure reducing valve to the

tank inlet is recommended. If the pressure from water mains exceeds 6 bar, a reducing valve is

necessary. Should the water be too hard, install a water softener before the tank. In case the water

contains mechanical impurities, install a strainer.

6.5 - Commissioning

The tank shall be

fi

lled up together with the heating system, respecting valid standards and rules.

In order to minimize corrosion, special additives for heating systems should be used. The quality of

heating water depends on the quality of

fi

lling water at commissioning, on the top-up water and on

the frequency of topping up. This has a strong in

fl

uence on the lifetime of heating systems. Poor

quality of heating water may cause problems like corrosion or incrustation, esp. on heat transfer

surfaces.

Hot water quality must meet the conditions shown in the Table of limit values for total dis-

solved solids in hot water on this page.

Fill the heating circuits with the appropriate

fl

uids and air-bleed the entire system. Check all connec-

tions for leaks and verify the system pressure. Set the heating controller in compliance with the docu-

mentation and manufacturer’s recommendations. Check regularly proper function of all control and

adjusting elements.

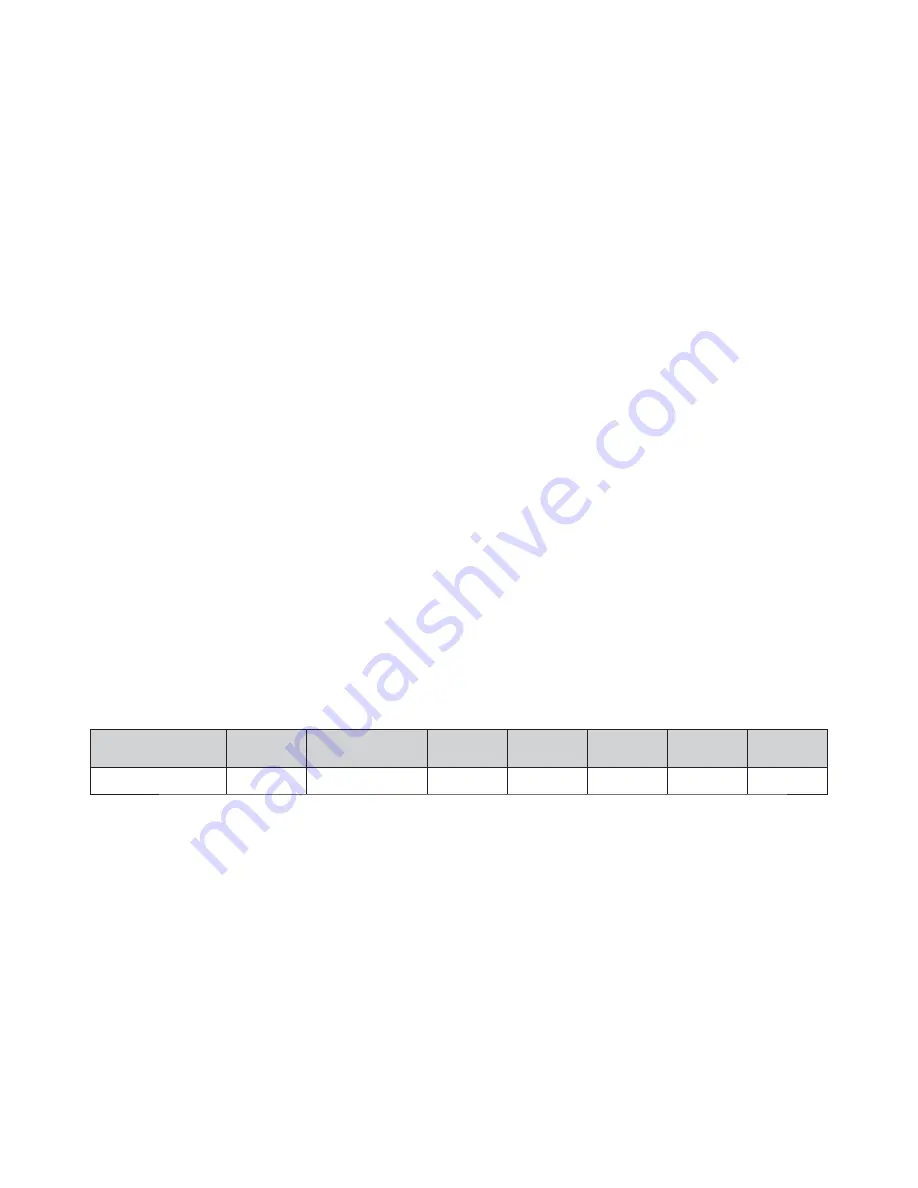

Table of limit values for total dissolved solids in hot water

Description

pH

Total dissolved

solids (TDS)

Ca

Chlorides

Mg

Na

Fe

Max. value

6,5 - 9,5

600

mg/l

40

mg/l

100

mg/l

20

mg/l

200

mg/l

0,2

mg/l