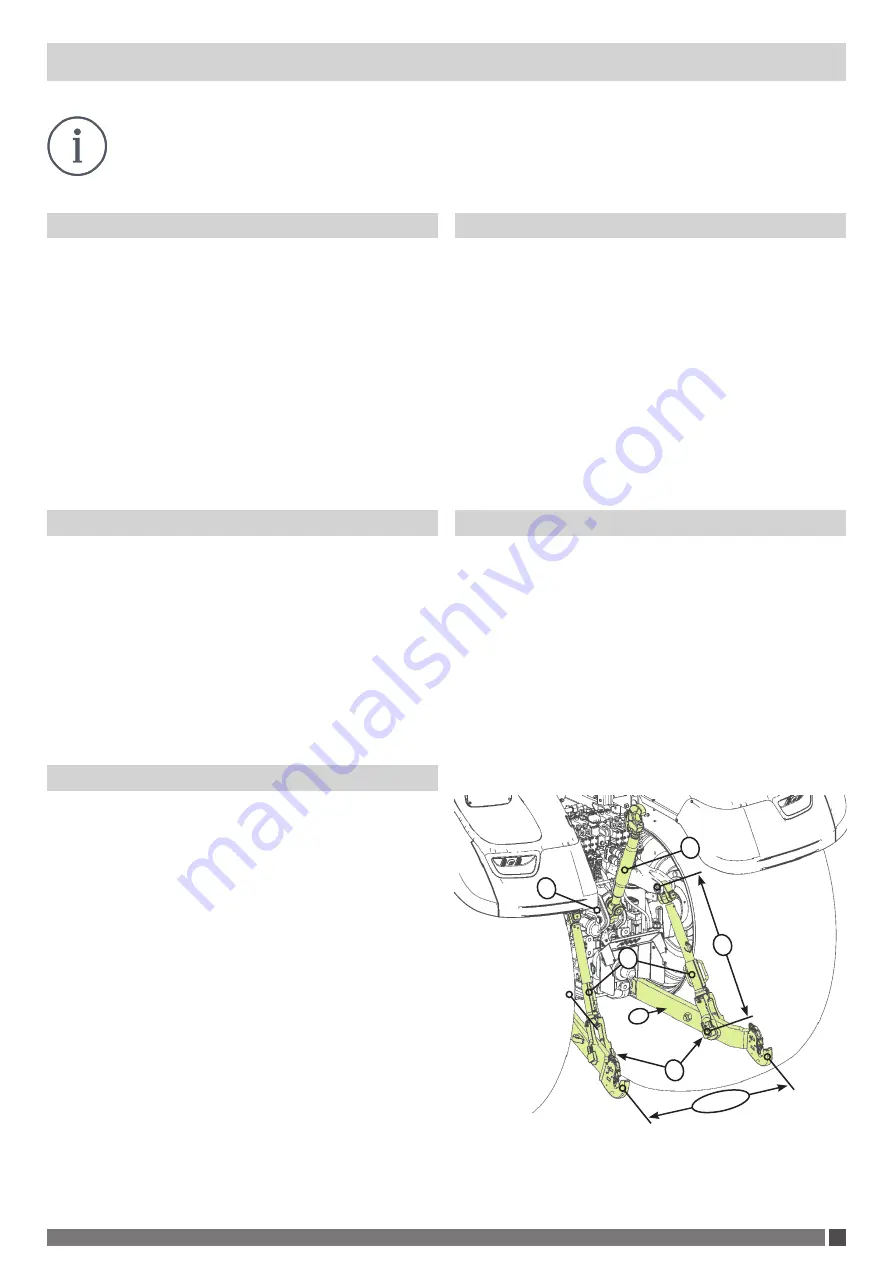

D

B

C

E

A

F

G

PREPARATIONS ON THE TRACTOR

Please read the manufacturer‘s operating instructions in full before starting the tractor, act accor

-

ding to the manufacturer‘s instructions and be sure to observe the safety information and regula-

tions contained therein, as well as the general instructions.

Tires

Hitch rods

The inside track width should be as identical as possible at the front

and rear axle, adjust the track width if possible.

Make sure that the tire pressure is the same on all axles of the to

-

wing vehicle. A different tire pressure causes the towing vehicle

to tilt and has a negative impact on the operation of the attach

-

ment.

When working in the field, low tire pressure has a positive effect

on traction, fuel consumption and soil protection. We therefore re

-

commend choosing the lowest possible tire pressure (taking into

account the manufacturer‘s instructions).

For road transport on a paved surface, please observe the manu

-

facturer‘s instructions.

¾

The two lifting struts (A) must be set so that they have the same

length (B) on both sides from the center of the pin to the center

of the pin.

¾

The pins of the lifting struts (C) must be locked in a rigid position

and must not be in the slot or have any height clearance.

¾

The lower link struts (G) are to be set so that they are locked

against sideways swinging during road transport or in the raised

state, in the lowered state (when the device is working in the

ground) the side struts must be able to swing freely and must not

be fixed.

¾

The leg dimension between the two center hook points (D) must

be set exactly to the leg dimension of the device. When lowered

(when the plow does work in the ground), the side struts must be

able to swing freely and must not be fixed. Make sure that the full

pendulum clearance is set for the respective mounting dimensi

-

on of the plow´s linkage tower.

¾

The top link (E) should be pegged in the hole group (F) of the to

-

wing vehicle so, that the imaginary extended line of the top link

in intersects the front axle of the towing vehicle (working position,

see depth adjustment). In this way, the tire-slip can be reduced

to a minimum and the electronic hoist control can work correctly.

Ballasting

Correct ballasting reduces tire slippage, and thereby also redu

-

cing fuel consumption. If the front ballast is too low, the all-wheel

drive and the steering of the towing vehicle will work restrictedly.

Wheel weights on the rear axle can reduce the tire slippage to.

When choosing the ballasting, always observe the country-spe

-

cific rules of the legislature. As a basic value, you should make

sure that the front axle is permanently loaded with 20% - 40%

of the vehicle‘s empty weight. Always make sure that the ma

-

ximum permissible axle loads of the vehicle are not exceeded

and observe the specifications and recommendations of the

manufacturer.

Suitability of the tractor

Basically, the towing vehicle must be checked for suitability for use

with the attached device. Among other things, the following para

-

meters from the type certificate must be observed.

Check whether the following load specifications fit for the device

before you connect it:

¾

maximum permissible total weight

¾

maximum permissible axle loads

¾

maximum permissible trailer load

¾

maximum permissible vertical load

¾

Load capacity and air pressure limits of the tires

¾

the prescribed braking decelaration must also be adhered to

when the implement is connected

¾

Lifting power of the hitch

¾

Category size of the hitch

Electric hitch settings

Lock all control units and the hitch control against unintentional

operation during road-transport.

The operating mode „position control“ must be selected during

coupling / uncoupling of the device and during road-transport.

The operating mode „traction control „ can be used during field

work. We recommend setting the traction control as low as possib

-

le, a strong control frequency would have a negative impact on

the work result.

Coulters and processing tools are hardened components, placing

them hard on the ground can cause such components to break.

Therefore, set the lowering throttle as slowly as possible.

6

www.regent.at