6 | U1500E-11 Gas Fireplace

Framing & Finishing

U1500E-11 Gas Fireplace

Note: When constructing the framed opening, please

ensure there is access to install the gas lines when

the unit is installed.

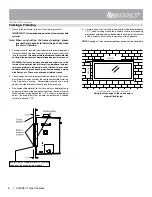

2. For exterior walls, insulate the enclosure to the same degree as

the rest of the house, apply vapour barrier and drywall, as per local

installation codes.

(Do not insulate the fireplace itself and/or the

venting. Clearances must be maintained as per this manual.)

WARNING: Failure to insulate and add vapor barriers to the

inside of the exterior wall will result in operational and per-

formance problems including, but not limited to: excessive

condensation on glass doors, poor flame package, carbon,

blue flames etc. These are not product related issues.

3. The unit does not have to be completely enclosed in a chase. You

must maintain clearances from the vent to combustible materials:

See "Clearances" section. Combustible materials can be laid

against the side and back standoffs and the stove base.

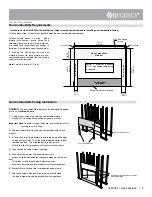

4. Non-combustible material (ie. tile, slate, etc) may be brought up to

and overlap the unit (top and bottom) ensuring that the maximum

thickness does not go beyond the 1-1/2" as shown in the diagram

below. The faceplate will not be able to be mounted if finished

material is beyond 1-1/2".

1. Frame in the enclosure for the unit with framing material.

IMPORTANT: The framed opening must be of non-combustible

material.

5. If material such as brick, stone, etc extends past the faceplate depth

1-1/2", when finishing around the faceplate, the minimum opening

dimensions noted below must be adhered to ensuring for the removal

of the faceplate and for the safe operation of this appliance.

NOTE: Spacing of 1"around the completed surround must be adhered to.

Unit shown with inner door frame only

Using the clean edge of the unit shown in

a typical tiled facing.

49-7/8"

18-1/16"

Ensure front of facing material is flush with

the edge of the flange on the fireplace.