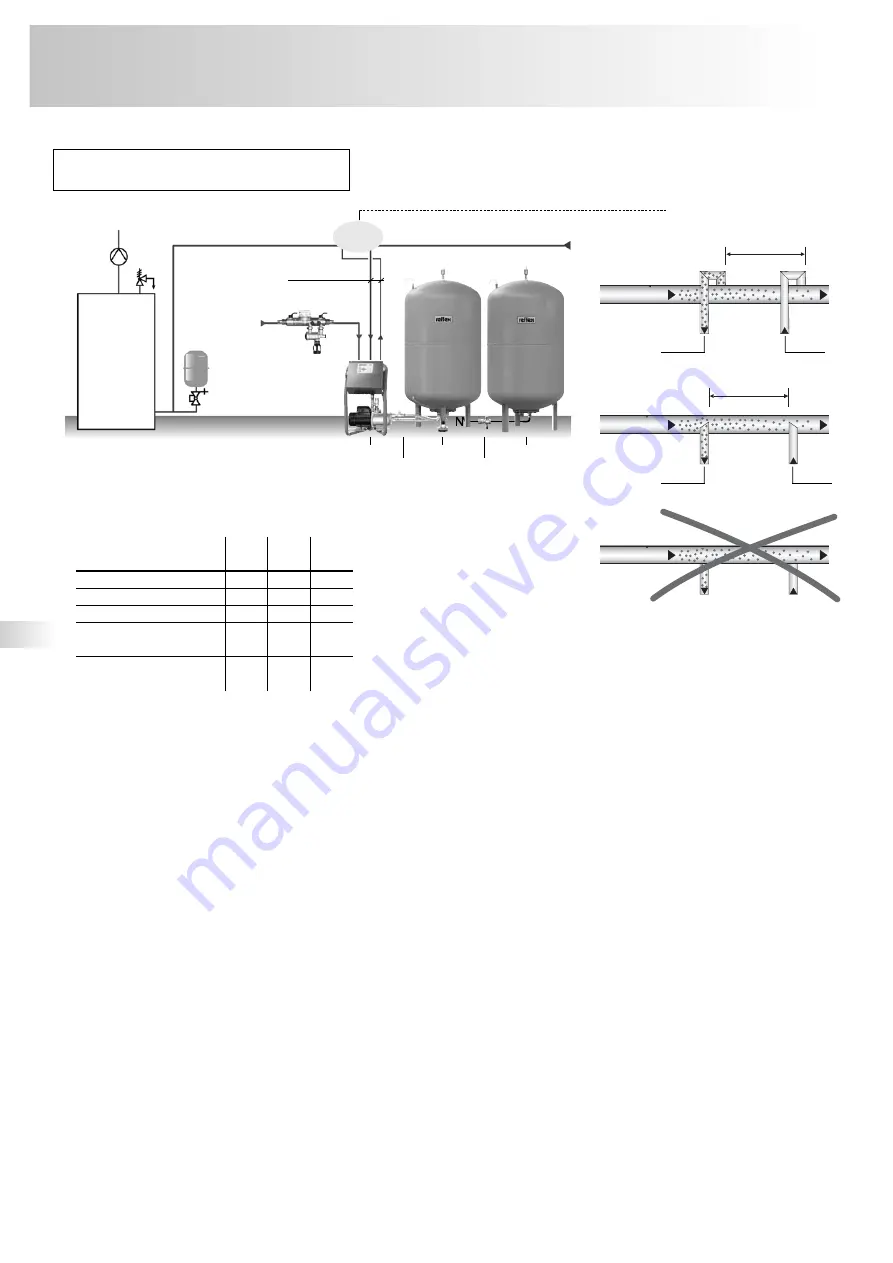

The additional degassing function means that two expansion

lines (O, P) must always be installed for the ’variomat’.

Regardless of the ’variomat’ nominal connection width, the

size of the expansion lines must at least correspond to the

values specified in the table.

Integrate the overflow line (O) ahead of the pump line (P)

seen in the direction of flow of the system.

Integrate the ’variomat’ in a representative main flow of

the system.

Max. medium temperature at the integration point 70 °C,

max. glycol content 50%.

To avoid coarse dirt entering and overloading the ’variomat’

dirt trap, integration must be performed according to the

above diagram (see “Close-up of integration point”). Flush

the pipelines of the heating system and the potable water

make-up unit prior to start-up.

In the case of water heating systems according to DIN 12828

(formerly DIN 4751 P2), it must be ensured that only

protected shut-off facilities or none at all are installed

between ’variomat’ and the heat generators. Otherwise the

heat generators must be individually protected

(recommended for ’variomat’).

Individual protection:

Owing to the sound degassing

performance of the ’variomat’, it is recommended even

with single boiler systems to install a diaphragm pressure

expansion vessel (for instance ’reflex N’) at the heat

generator to minimise the switching frequency.

Connection line for make-up:

If the make-up

line is connected directly to a potable water system, reflex

’fillset’ (shut-offs, system separator, water meter, dirt trap)

must be installed upstream. If reflex ’fillset’ is not installed,

a dirt trap with a mesh size

≤

0.25 mm must at least be

installed to protect the make-up solenoid valve. Keep the

line between the dirt trap and the solenoid valve as short as

possible and flush.

If the automatic make-up facility is not connected, the

connection (WM) of the make-up line must be sealed with

a R ½ plug.

Note:

If manual make-up is not performed in time, the

’variomat’ pressure-maintaining station will switch to an error.

The normal pressure at the ’variomat’ make-up solenoid

valve must not exceed 6.0 bar. Install a pressure reducer

upstream if required.

- p

0

= minimum operating pressure,

→

p. 15

- expansion lines > 10 m length install one

size larger

Connection of the ’variomat’ control unit,

expansion lines

Expansion lines (O, P)

≥

500

Main flow V

circuit water

≥

500

Main flow V

circuit water

rich in gas

low in gas

rich in gas

low in gas

Main flow V

circuit water

Close-up of integration point

from above

from below as

immersion tube or

from the side

butt-welded

from below -

not permitted

DN

DN

DN

DN

25

32

40

50

variomat 1

x

variomat 2-1/...

x

variomat 2-2/35

x

variomat 2-2/...

x

p

0

≤ 3.5 bar

variomat 2-2/...

x

p

0

> 3.5 bar

Water make-up

p

≤

6 bar

reflex ’fillset’

max. 70 °C

Control unit

VG basic vessel

VF secondary vessel

Connection set G 1

reflex ’SU quick

coupling’ R 1x1

Line DN 25 on site

Sizing of

expansion lines

WM O

P

Close-up of

integration

point

reflex ’variomat’

Assembly

10